Work Weak

I’d like to tell you about all the exciting work I did today at Hometek, and it was exciting to me. But gluing, planing, changing shaper bits and re-sawing cedar isn’t lofty on anyone’s dance card except an avid shop rat.

I’d like to tell you about all the exciting work I did today at Hometek, and it was exciting to me. But gluing, planing, changing shaper bits and re-sawing cedar isn’t lofty on anyone’s dance card except an avid shop rat.

This was Jim the finish carpenter and foreman’s first day back in two weeks after burying his father, and he’s on track to depart in December, never to saw wood again. He’s been a craftsman for his entire life, as was his father and his father’s father. Poor bastard, it ceased to be fun for him years ago.

But even the repetitive acts your favorite shop rat buried himself in was fun, fun to use pro tools, and watch two pro’s work.

The middle of what seemed like a long day (likely it seemed that way because my knee hurt) was devoted to replicating two different cross-sections of siding. It was a pleasure to see Tom and Jim painstakingly put their tools to making exact repro’s of the samples of siding.

Mid-to-late afternoon was forming the arch that matches the curve of the top of the Hayward Gates. How is this done?

1/4″ Masonite is lashed to 12 bookend shaped supports which are screwed to the top of the worktable at the desired curviture – once the thin strips are all smeared with glue, we press the laminate to the masonite and clamp.

We re-sawed and planed down 2 x 6 cedar into 1/8” to 3/16” thick billets. Then, after screwing a flexible form to one of the work tables, we slathered on glue (both sides) and put the billets, one by one, against the form, then clamped the built-up lamination home.

TDAY –

The day flew by, all on the Hayward Gate. The first hour and a half sanding, then re-sanding, then re-re-resanding as my fingers got educated, thanks to Jim Ream.

That curvey trim at the bottom (actually the top panel of the gate) was the trickiest, particularly in getting the meet angles perfect.

The rest of the day: fitting (not very well, but well enough, I hope) the inset trim into the panel/frame.

Tired.

Called CalAm Water about the 10x usual water bill. Morris promises an investigation 6/19.

6 18 –

Slept better, no Dad Is Dead Dreams.

Usual mooky morning cruise to 2022 17 Mile Drive. Jim Ream on the cell with somebody. I hazard small talk as we begin work. He’s all meh. Transforms into a window forming automaton, and worse, changes the radio from KPIG – which, at times can actually be amusing – to something called The Hippo, which plays only rock and roll from the Nixon through the Reagan Administration. Happily, the saw, shaper, dust control noise drowns this out most of the time I’m spending all morning filling brad holes in the Hayward gates. And then sanding it all smooth.

Probably devoted twice as much time to this as was necessary, since it to be primed the painted, and primer and paint will fill gaps up to about 1/16”, which were the max on the corner trim.

I go over to The Automaton just to see what he’s doing. I am ignored. But I shouldn’t take it personally. Jim has allergies, or so he has said, and it must be painful for him, he’s ever vacuuming up, but doesn’t wear a dust mask, which is strange. And he gets stranger.

One other strange thing I’ve noticed is the shifting sense of standards. I’ve watched Jim and Tom agonize over a minute difference between some trim they have to replicate and the output of the shaper; and then twenty minutes later dismiss some gross flaw (but not one that I’ve created or overlooked) “It’s just a gate.”

After the lunch break, The Automaton switches the radio to the Giants – White Sox ball game, which I think is great (except for the advertisements) and I compliment him on the choice (he’s got a SF sticker on his van’s driver’s side window). The Automaton does not deign a reply.

Shrug.

I finish priming the Hayward gates and so need another job. The Automaton is lost for what to have me do, but then causes me to mark the mortise locations on the window parts he has laboriously created over the past day and a half.

I’m lost because I do not understand how he has laid out the parts, what parts go where and why there is only a bevel on one but not the corresponding parallel piece.

The Automaton shakes out of solar orbit, “I never make a mistake.” “I lay them out in pairs” I don’t know from pairs or in what sequence. But I suppress my innate desire to say, “Whenever somebody says that they never make a mistake there are only two possibilities: 1 they are lying, and 2 they ain’t doin’ nuthin.”

But fortunately, I say this not and Jim takes the one minute to trot me over to one of the original windows and shows me their detailed construction.

I get it. Bottom only is beveled to match the sill, the two sides and top the same cross-sectional dimensions.

And within three minutes I see as many mistakes. He’s mislabeled sets of window parts; he’s shattered some of the tenons ripped on the table saw (which makes marking for the corresponding mortises difficult, and he mis-cuts one of the mortises.

I say nothing, which is galling. But I’m The New Man and have little to no standing.

It does bust him out of his robot mode. Even gets me the jig saw when I’m handing sawing apart some junk lumber. Wants to know can I bevel a door edge with a plane?

Sure.

He busts out a tool I’ve never handled – a power plane. I defer.

Tom puts me to distressing a panel sample; on one side are the marks he’s imposed with a scraper and a wire brush. “Here’s your pattern.”

I fail to hear this in the way I should have and take to the sample with markedly more destructive effect than “the pattern.”

But I’m only mildly ding-donged for this. I can’t be all wrong all the time, can I?

Quitting time and now back to the Castle for my other jobs.

Wilder is dropping by to collect the two raisin trays I’ve shellacked; and Claire of Rygg is bringing by a 20 year old dining room chair needing repair.

They both arrive at the same time.

Claire’s chair has the back splat busted out. She opts for the quick and easy Just Glue It Back In and Fill The Missing Shattered Part With Putty, Then Stain. I quote her a price too high for the value of the chair, but lower than her expectations.

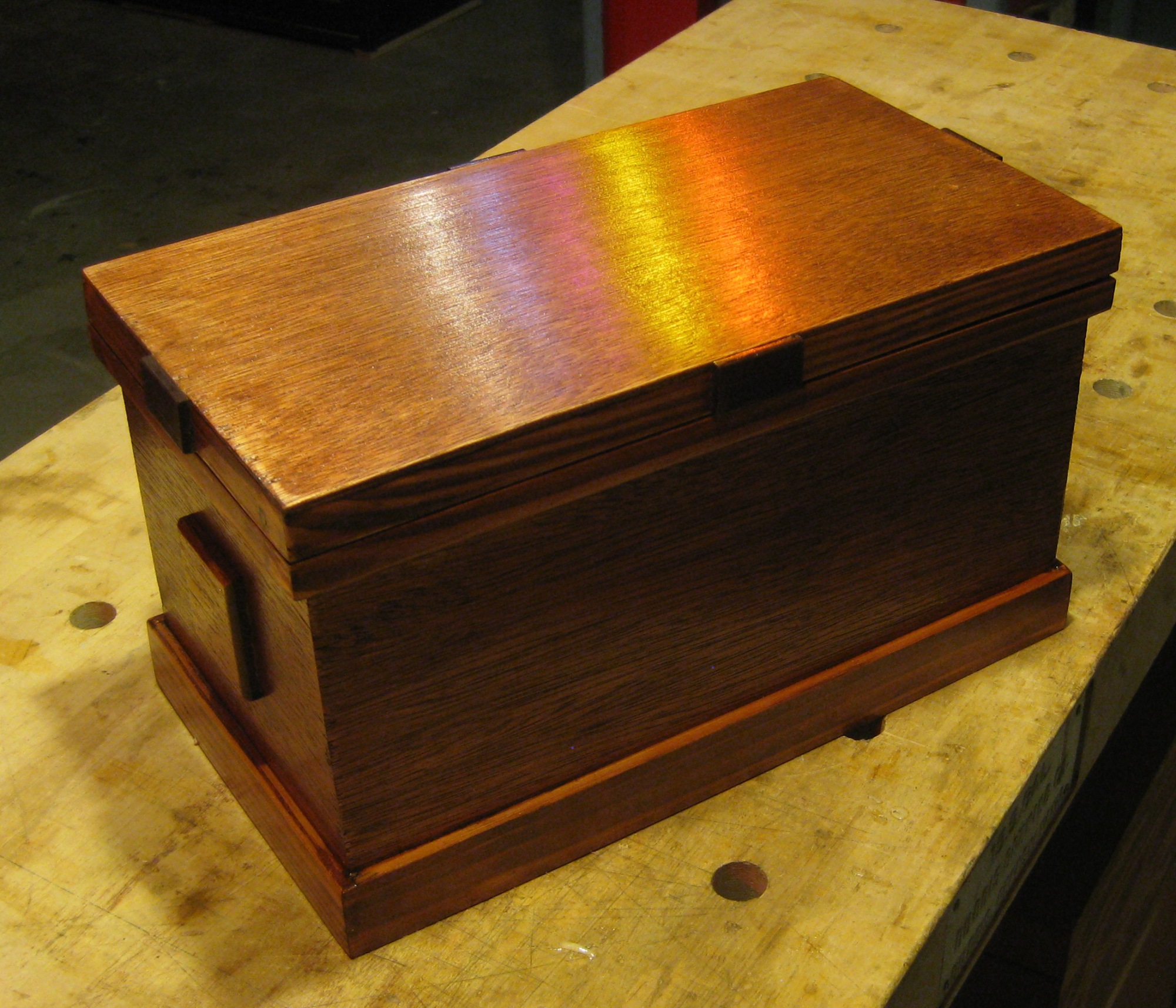

To Wilder. We find the website of the vineyard owner he’s been hustling in Hollister (Leal) and cop one of his site’s images which I print out, crop and glue to one of the raisin trays. We aim it to be a sort of loss-leader giveaway in hopes of a stout order for 100 at $40 per.

I’ve got to get off my feet and so get rid of the clients and into the evening’s relaxation.

TDAY – 0700 and Jim the Automaton Speaks! And now I’m sorry I got him started. He’s pathologically bitter. F’ing Aquarium this, ruined Monterey, and GD tourists that. Not my problem, and I still admire his skills. He’s a door fitting, window fabricating machine.

I’m back on priming the Hayward Gate, the two sides of which are not quite as heavy as they were earlier in the week. Knee feels better too.

Here the Bossman is wondering why there is a faint blond smear next to the furring strips I applied – it’s not glue, I didn’t use glue on this side.

The Bossman puts me on the GTE Door. Heavy mutha with a central fenestration for the 2’ x 6” glass pane, which I fit into place cutting the furring strips to hold it there, caulked on the outside, no glue on the inside furring strips. Then it’s Plastic Wood fill the minute crevices and nail holes, then finesse out the extruded caulk.

More doors arrive. On one of them – The Souza Door, it’s a damned heavy alder raised panel – I’m told to remove the door from the frame, take off the hinges. And then load it on the CNC table. This could be my big break. Maybe Tom is going to train me on its use.

And it is and he does, or at least introduces me to the UI, it’s a graphic interface. Our first job is to precisely (or as precise as our eyes can read a micrometer) dimension the door with the landmarks needed for the eventual task, which is to hog a ¼” deep recess out of the two raised panels into which will go chalk board.

You start at one corner of the door establishing it as the X Y Z zero point in this case the left lower corner of the door on the table: X is left and right, Y up and down, and Z vertical relative to the CNC table.

From that zero, zero, zero point, the operator ‘builds’ the two-dimensional shapes of relevancy to the impending operation, in this case the rails and stiles of the door, and the absolute position of the edges of the raised panels.

The 1/2″ end mill is gently but relentlessly hogging out the exact shape of the door panels – less a 1/4″ border 1/4″ deep.

This is hot stuff. Because once we’ve established these dimensions, we can command the end effector – typically some sort of router bit – to any spot we desire in the Cartesian coordinates and cause it to move through any cutting sequence we wish.

It’s quitting time before I feel my lesson is complete, but maybe I can pick it up tomorrow.

FDAY –

But I mean that in a good way, today is payday. The first paycheck I’ve been handed in …. Since … actually, time does not go back that far. I’m netting $7 less per hour than I need to keep my financial nose above drowning, but from small beginnings….

My day at Hometek had me double checking the eyeball settings on the CNC, then caulking the Bill Hayward Gates. From here I shadow The Boss in setting up the CNC to hog out for the chalkboard into the door, then first distress (lightly) with a paint scraper and a wire brush, the Kampe Door and then second give it a coat of Gunstock stain.

Jim the Former Automaton cranking on the McLauglin Window Parts is kind enough to offer me latex gloves for the staining, but as I explain to him later, they dissolve, but I appreciated his gesture.

The Day’s Incongruity: Hometek HQ is in a storage facility just south of 17 Mile Drive, the butt end of the fence adjacent to Pebble Beach. For the lunch break, I lurk around back, find a bike path and this a jog through the stunted, overage scrabby pines leads to a paved golf cart road. Here’s a bench on which to enjoy the noon repast of a chicken pepper onion cheddar sandwich and pretzels. A bench on the 13th tee of Spanish Bay (maybe all the holes have names, this one is called Wee Precipice, probably because there is no fairway, the tee looks over a native, brown weedy arroyo, the 3 par hole a green island 192 yards toward the Pacific) where I watch three foursome’s hook into the rough. What was strange was that here I am, some dull looking mook who obviously Doesn’t Belong next to the tanned movie stars and wealthy retired cardiologists and nobody suggests I Move Along.

Another of the day’s incongruities was the radio Jim had blaring in the shop. Hippo. Jethro Tull, Foreigner, Foghat for fucks sake, Aerosmith, Boston, Lynyrn Skynyrd … and in spite of the onerous commercial spots, I’m rockin’.

I’ve Broken Through.

End Of The Work Day – spirit across town to deposit That First Paycheck Since The Truman Administration, thence all the way to Marina and Grocery Cheaplet.

Navigate the weekend traffic back to the Working Man’s Castle to find on my drawbridge the two worthies: Prof and Curtis.

Story-telling is unconfined.

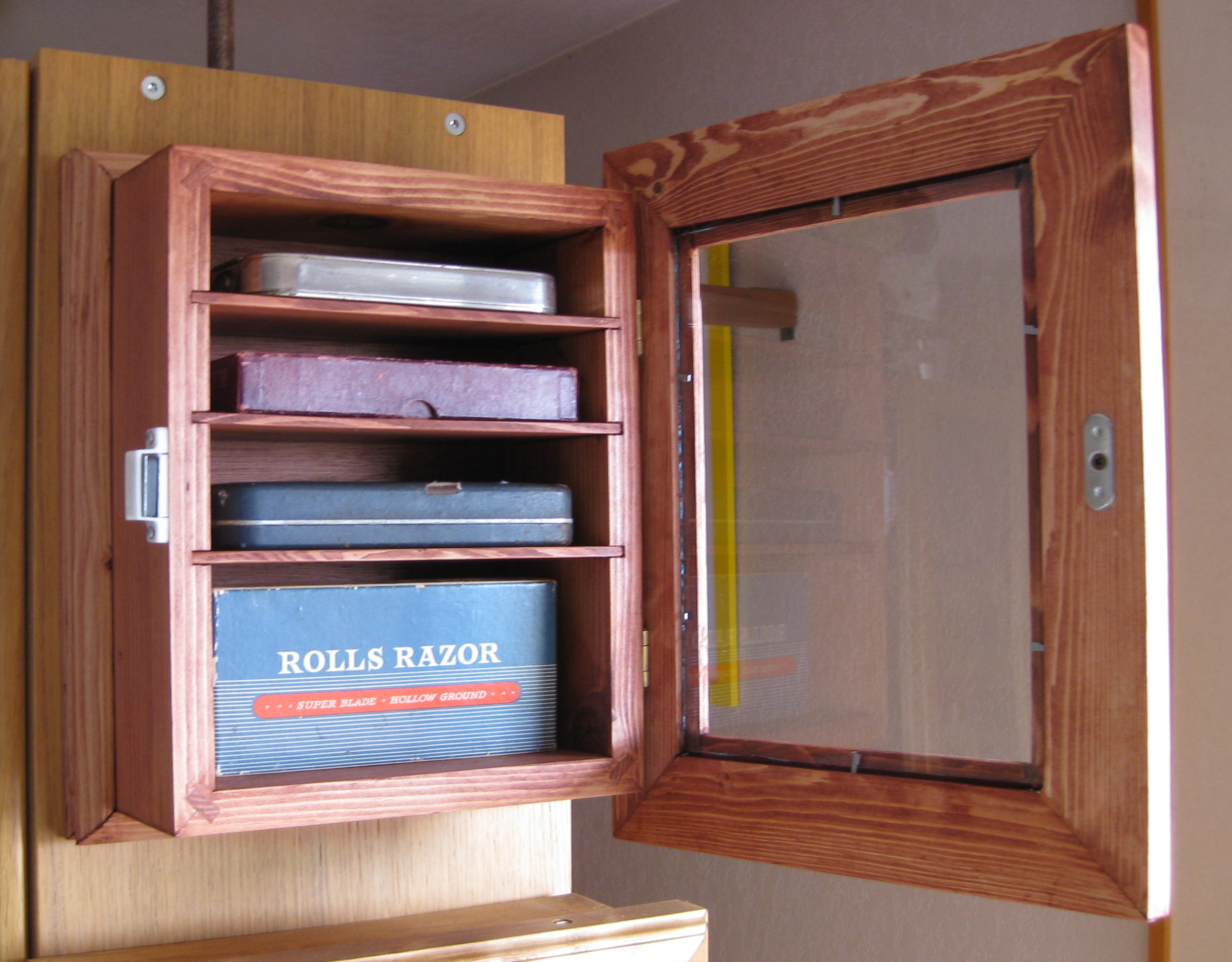

Sliding Access Large Book Cabinet

Sliding Access Large Book Cabinet  Rotating Display Cabinet

Rotating Display Cabinet  Tiny Display Case

Tiny Display Case

No comments yet.