First Last Saturday

Paul and his chief dauber Scott were here of the AM putting more soiled baby diaper color paint to the castle making it to sag from 11th Most Repellant Structure in PG to 13th, solely on strength of uniformity of overall dung tone.

Paul and his chief dauber Scott were here of the AM putting more soiled baby diaper color paint to the castle making it to sag from 11th Most Repellant Structure in PG to 13th, solely on strength of uniformity of overall dung tone.

The sound of the doorbell foretold the wonders delivered via FedEx from Amazon: a replacement (we hope) desktop computer fan, a tiny syringe of thermal paste, and two size Sasquatch shoe heel replacements.

I do not know if the computer fan needs replacement, but the inconvenient automatic shutdowns when the reboot indicates a thermal event suggest a thermodynamic issue. Happily, the $15 replacement fan nestles into its new home without me having to use chisels, gunnite or bailing wire. And even though I was scrupulous in swapping out the old for the new, it seems that the air flow – on boot – is from inside to out. Does this matter? I know not.

That thermal paste? It’s a means of improving the heat transfer from processor to heat exchanger; its effect analogous to terminal grease on electrical connections.

Those Sasquatch heels? Try as I may, I can never seem to prevent wear on the outside heels of my dress shoes; and this with the installation of heel protectors. Can a handy fellow such as myself avoid the $45 buttram at the shoe repair shop with a $5 pair of Goodyear replacements?

He can try.

Sawing away the extant heel, in part, was but first of the challenges. The second was shaping flat the ugly, mangled cut surface of the heel, and third, clamping, once glued, the replacement billet. Have I just ruined a pair of foot gear? Tomorrow, if tomorrow there be, shall show us.

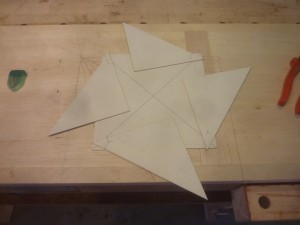

This one dimensional kinetic model seems to support the intention that if all four drawers pivot at the same time they will not interfere with each other …. too bad that can’t happen in society.

This day, formed a one dimensional moving replica of the simultaneous four drawer cabinet.

The boys down in Marketing are still working on a working title – used matte board and pins. The action seems to show that yes, all four drawers will pivot and open simultaneously IF all four drawers pivot and open simultaneously. The pivot corner will interfere with the adjacent drawer is they do not all pivot at the same time.

How to cause this to happen?

Some kind of mechanical linkage was my first thought, but I immediately discarded it for the more promising concept of a belt and gears. Each of the four drawers sports a gear and all four gears are linked via a toothed belt.

Concept validation awaits.

Just as I directed the portcullis lackey’s raise the drawbridge appears on the moor The Prof, fresh from a warfighter love-in in Tampa, FLO-dah. Long day, he needed strength in the form of 15 ounces prescriptions of Guinness.

CROSSDAY –

Not for me, taciturn, more like.

More at the next step in validating the concept of a belt and gears to open the four drawers of the prototype cabinet.

How to do this?

Build a mock-up.

In essence a working (one hopes) simulacrum that duplicates the main features of the intended design: four swiveling pie pieces pivoting on bolts connected by a flexible linkage. A base of ply, four pie pieces of ply, four ‘gears’ of cylindrical particle board and some string.

The ‘gears’ were shaped on the poor-man’s lathe and attached with screws to the pie pieces; both swivel on ¼” bolts. The string is fastened to one of the ‘gears’ and is wrapped around the other three. Tightly.

Test Results: a modest success. The pie pieces do indeed swing out nearly in unison. This illustrates the need for absolutely – and I can barely summon the chi to write these next words – the need for absolutely No Slack in the string, or belt what might even be better, endless chain on cogs.

Heady stuff.

SLACKDAY –

Well, more than usual.

Three pelicans soared over the castle; they usually do not appear this far inland, if we can call 150 meters far inland. One broke off and circled the block for a minute. Must be a good sign.

The St. Angeleians have set up a burn pit in the parking lot, figure for some singed heretics this evening. Not to worry, I’ve plenty of ammo.

The St. Angeleians have set up a burn pit in the parking lot, figure for some singed heretics this evening. Not to worry, I’ve plenty of ammo.

Plenty of time to futz around with two lights – one that fits into the disused space in the desktop; the other an improvement (waste of time) on the french fry holder light of two weeks ago.

All good clean fun.

FUNDAY –

But nothing about which you need alert the MacArthur Grant Selection Committee.

Sewed on some buttons to a new jacket from Sportsman’s Guide – a sort of black helicopter, East German Stasi blue job. The epaulets were sewn to the shoulder even though button holes were formed. As if a production run got 95% done and somebody pulled the NAH lever. Same with the two front chest flap pockets – button holes ready to button but no buttons.

Invested an hour in scouring rust from two of Harvey’s double-barreled ‘tools’ which had been neglected far too long here where the air is always replete with salt.

Then: nothing.

Sometimes doing nothing leads to fertile thoughts.

But not today.

TRIANGLEDAY –

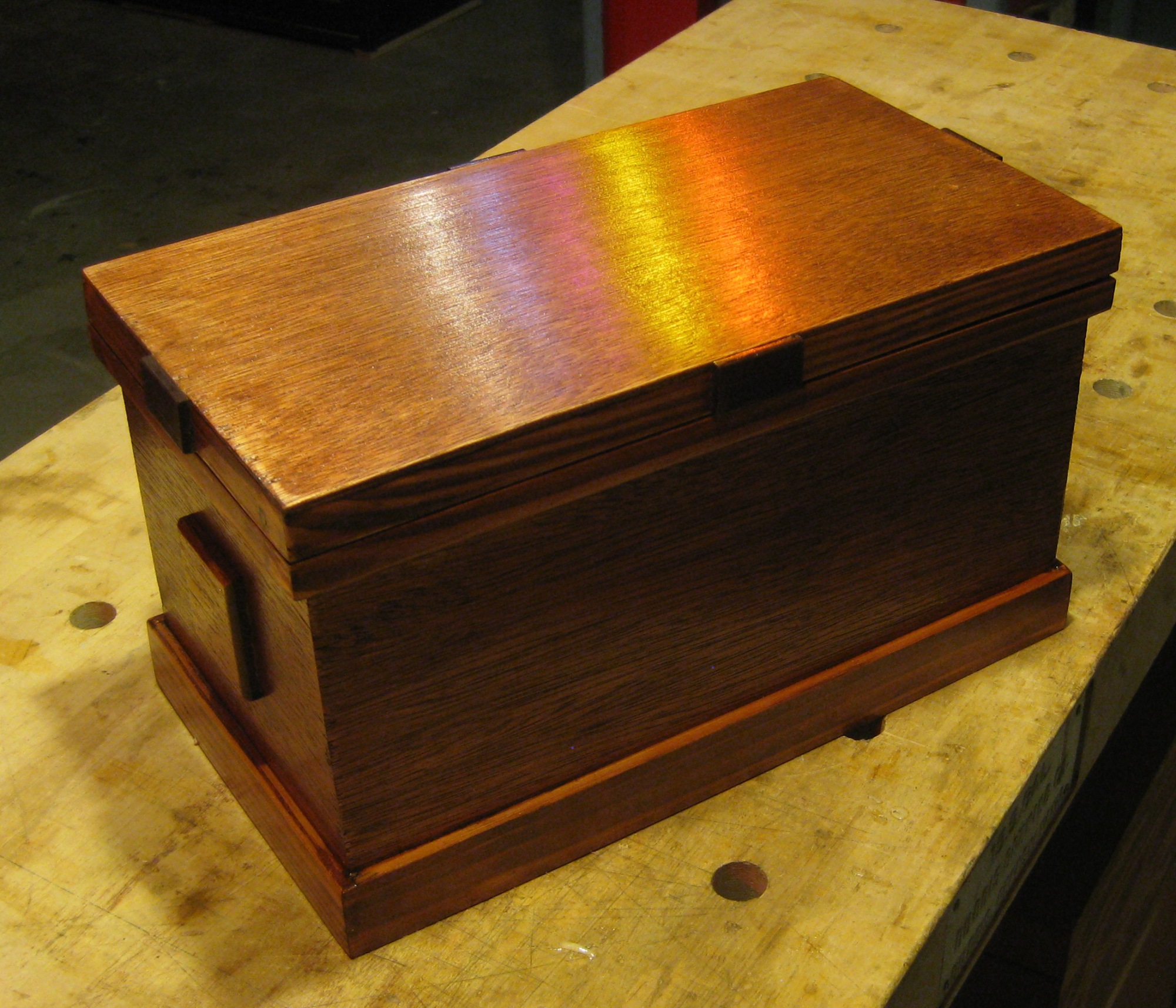

Enough fiddly-farting around not plunging ahead with the Quadra-Cabinet (I’m not thrilled with the focus group’s choice of the name for the four drawer pivoting simultaneous-open wood arranged in a sort of cabinet shape project, but their product is worth what I paid for it…), or at least forming the four drawers. How I’m to connect them with flexible elements to put all four in motion at the same time is still an unknown. Servo City serves up sprockets and chain, but at $50 – that’s a lot of dough these days for a prototype.

Each of the four drawers is formed from four parts: three sides and a floor. And some air. One of the drawer angles is 90 degrees, the other two are 45’s. At least in in our 4-dimensional existence. So far as we know.

Chose for the sides some surplus siding which was cut to about 10 cm width and planed to about 1.5 cm thickness – this was a deviation from plan, which specified a thickness of 1.0 cm, and this had repercussions downstream, but not fatal. Except for the 3.78 million microbes my dull saw blade moshed into intercellular goo.

Once the siding was cut to thickness and width, rough-cut to oversize for the three different lengths: 21.5, 22.5 and what looked like 29 cm on the full scale diagram.

Put the 45’s to one end off each, then formed the two short sides which meet at the 90 degree. Dry fit and clamp gave me the final length of the long, front aspect of each drawer. I didn’t measure it, took it directly from the dry fit. Krenov says that once you’re inside a project, forget about the measurements and go with the parts as they are.

Time for glue-up. Gluing and clamping the 90 degree angle was straightforward; but how to clamp the 45?

Time for glue-up. Gluing and clamping the 90 degree angle was straightforward; but how to clamp the 45?

HEY! I have some adjustable corner clamps which I set to 45 degrees. This got me close enough to bust out the brad gun.

The floors were readily cut from ply, then glued and nailed.

That extra 0.5 cm resulted in drawers which, while all being the same, have a 0.5 cm offset which I didn’t plan on. BUT, if ever the design could accommodate a central drive axle that would somehow motivate the four drawer sprockets (if four drawer sprockets there be…) that center gap could be just the tunnel in which the axle fits.

FUNDAY –

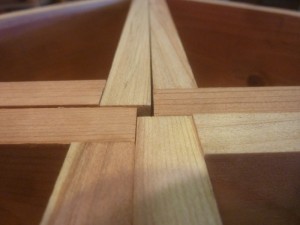

After a provisioning run – The Dump serves up gun lube and cleaning solvent and nearly a quart of turpentine, and a thought experiment at Homeless Depot where I arrived at 8 ½” copper pipe caps and a 9/16” diameter wooden dowel to serve as the drawer bearings and pivot – it’s run down the up escalator to The Shop.

On tap: scope, figure, fab the base of the Quadra Cab. I need/want enough overlap of the drawer footprint to accommodate the copper bearings which will be inset into the base – and the false top as well, but I need the base first, even though this thing will be assembled upside down, so’s I can make the top the same inside dimensions, but reduced outside dimensions.

I chose for the base some of Curtis’s surplus flooded out bamboo floor which I cut to about 9 cm width, then planed off the under corrugations. It’s too thin to seat the copper bearings, but I’ll position the feet such that the drill through for the bearings will bite into them.

I chose for the base some of Curtis’s surplus flooded out bamboo floor which I cut to about 9 cm width, then planed off the under corrugations. It’s too thin to seat the copper bearings, but I’ll position the feet such that the drill through for the bearings will bite into them.

Once the base frame was in glue up, turned to making a template for the dowel hole through each drawer, hoping that this will put the holes for the dowel, and for the copper bearing in the same position in each corner of the base. The top of each drawer will need something of a gusset spaning the corner to provide more stability to the dowel.

Whence tomorslack – can unclamp the base, put on the feet, drill the drawers, and then dry fit the drawers on the base to site the lower bearing holes. If tomorslack there be….

BEDAY –

Sky clear at 0130. Sky clear at 0330. Rain begins 0530. In late April? But we are owed by the gods. Delightful.

Sky clear at 0130. Sky clear at 0330. Rain begins 0530. In late April? But we are owed by the gods. Delightful.

For someone having a roof over their heads.

Less delightful hustling the tools off the Slack Deck when freshets waft.

Tools needed for form the false top for the Quadra Cab.

But we are ahead of the story. Yesterslack experienced Design Aphasia when I bought those copper pipe caps thinking (wrongly) that the dowel would pivot inside same.

No. The dowels are the only physical connection between the base and the cabinet top. The drawers must pivot ABOUT the dowels, but the dowels themselves cannot rotate. At least for this, initial, blindly groping through design.

While I’m waiting for the vision, trundled over the ox cart path to ye ACE of yon hardeware whither Plan ye A was for to find HMPE sleeve bushings in a 9/16” inside diameter. Ahem. On to Plan B which was to procure a dowel that just fit inside the sliding door finger pulls I had eight of.

Reason: the drawer needs to pivot, yes? Yes. I do want the drawers to pivot on the dowel, but not wood-to-wood contact. The finger pulls will isolate the drawer from dowel. Still unresolved is the bearing surface in contact with the weight bearing finger pull.

Also unresolved is the flexible tension element which translates linear to rotational movement (read: sprockets and bike chain).

Amid the unresolving comes another deluge and The Prof bearing Strength Potion and more significantly, Gnuuggies mutt!

Slack is unconfined.

PARTYDAY –

Ahead of schedule on party planning, behind the thought curve on implementing drawer swiveling on the Quadra Cab.

What is wanted is a gusset across the pivot corner which will support the finger pull against the through dowel. Stay with me.

Excised across that corner, then cut triangular shapes from bamboo, then nailed/glued those home.

Excised across that corner, then cut triangular shapes from bamboo, then nailed/glued those home.

Drilled for the dowel, then opened the hole a tad on the spindle sander to accept the finger guides. Gripping stuff, eh?

Holey Moley! Look at the time! I’m late for being too early for party – The First Last Saturday – prep: build Nana’s (somewhat modified) Mac & Cheese, bake the bread, set up the Fence Grill and array the Garage for Group Slack.

The First Last Saturday: surprise guests, absent friends, choice beverages, ending all too soon.

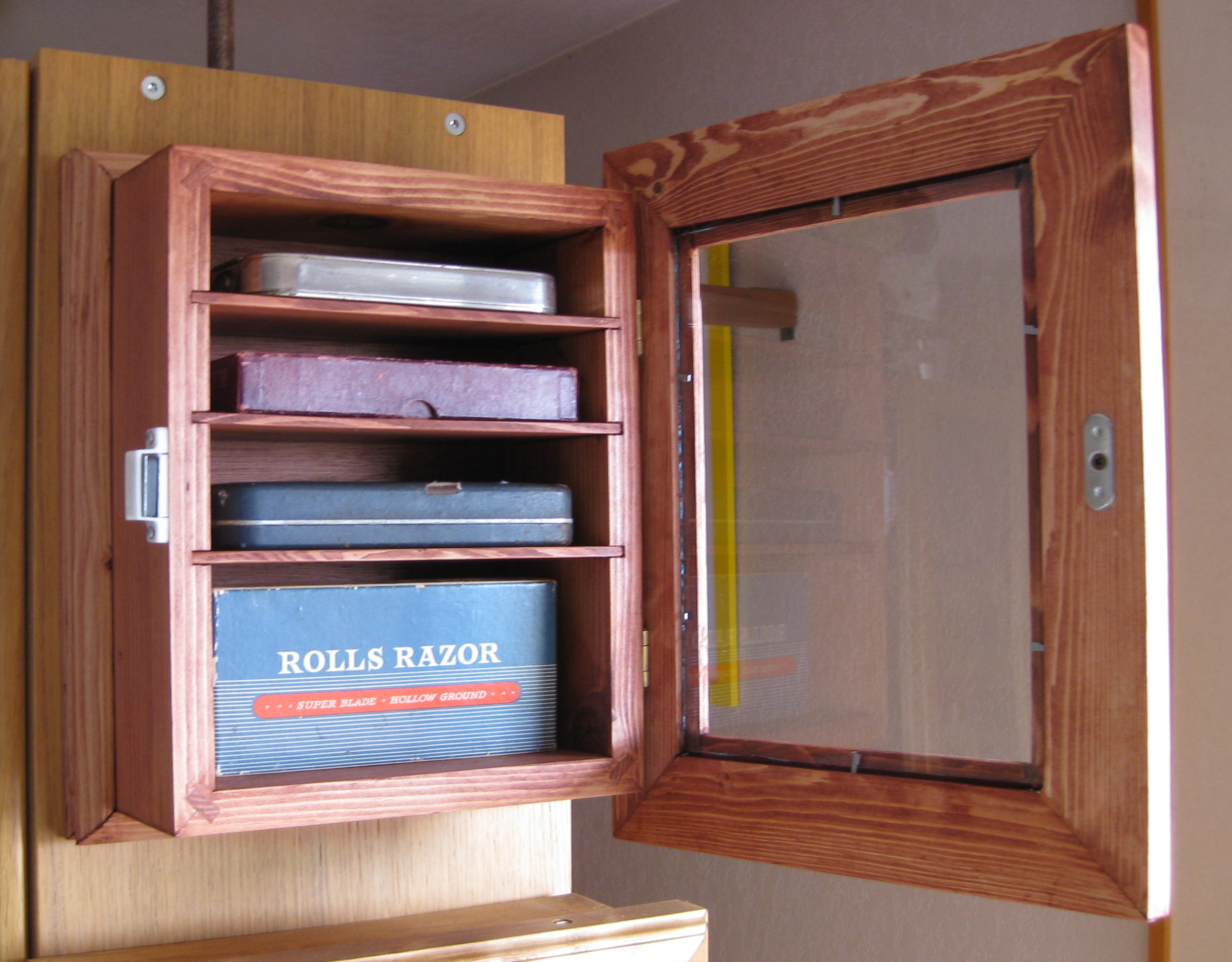

Kelly’s Tool Kit

Kelly’s Tool Kit  Whirling Dervish

Whirling Dervish  Space Juice Tankard

Space Juice Tankard

No comments yet.