Angles

Enchantment, I’ve been there without knowing why or how. I’m amid deeply spiritual beings in the form of dowdy matrons hawking knit goods and crèche filler at what seems to be a swap meet mall. But it’s more, much more. The place is imbued with magic. Each ill-dressed crone resonates with spirit, I’m drawn to their energy, feel it inside of me, wonder at their tchotchke’s suddenly more than just carvings and painted décor. Each and every moment is resonant with an unseen but deeply felt color, depth, perception and beauty. Except for that rubber horse head that tops a poncho; true, a fine rain garb well out of the ordinary, but there are no appendages or holes for one’s arms, so in spite of being monstrously cool, it is too impractical for stormy weather, at least outside of tramping about the moors frightening away the evil demons.

Enchantment, I’ve been there without knowing why or how. I’m amid deeply spiritual beings in the form of dowdy matrons hawking knit goods and crèche filler at what seems to be a swap meet mall. But it’s more, much more. The place is imbued with magic. Each ill-dressed crone resonates with spirit, I’m drawn to their energy, feel it inside of me, wonder at their tchotchke’s suddenly more than just carvings and painted décor. Each and every moment is resonant with an unseen but deeply felt color, depth, perception and beauty. Except for that rubber horse head that tops a poncho; true, a fine rain garb well out of the ordinary, but there are no appendages or holes for one’s arms, so in spite of being monstrously cool, it is too impractical for stormy weather, at least outside of tramping about the moors frightening away the evil demons.

Thursday. O’boom at an all-time low. Must remediate. Do so.

Dump. JohnsonArts saves 28 kopeks, nothing to buy.

Grocery Cheaplet. All-time low out the door: $9.95

Ka-nob Hill would have matched that tab save their 39% overcharge.

Charge down to The Shop on the mercury reverse polarity slide. It’s drawing time.

On the hook for the Doggie Cenotaph as I’ve cashed the check for half my fee. Midnight Study Hall produces more issues than answers. Full Scale Drawings Mandated.

The Prime Conundrum: What do the verticals that connect the top and bottom pentagons look like in cross-section? This is the prime issue as months ago, in preparation for this day, I prototyped a 5 sided figure. Feel 69.2% confident can do so again to adequate tolerances in wenge, if that’s what the Glaswegan wants. Top and bottom the same, maybe the top ½” inside the footprint of the bottom.

The Prime Conundrum: What do the verticals that connect the top and bottom pentagons look like in cross-section? This is the prime issue as months ago, in preparation for this day, I prototyped a 5 sided figure. Feel 69.2% confident can do so again to adequate tolerances in wenge, if that’s what the Glaswegan wants. Top and bottom the same, maybe the top ½” inside the footprint of the bottom.

But the verts, the verts have yet to be thought through.

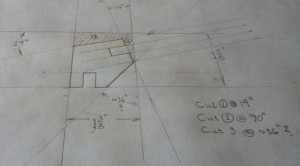

Full scale drawing (second of two) does indeed prove suggestive. And then it also indicates the cross-section of the verticals.

It’s a freakish 76 and 18 degree slant to the sides with 3/8” cut-outs to hold the glass. How to make …. if make it can be.

Wrack my tiny brain on how to slice wood into the cross-section. After a couple of false starts (finishes) start again with a rectangular cross-section, which surely any start will be, then draw in the desired form. This demonstrates how to run an 18 degree cut first, then using that surface as the register, slice 90 degrees to that. These two can then be dado’ed for the glass; the poignant inner excess can be …. will be … might be …. zarked in some manner not yet known.

Nothing for it but a test programme leading to a full-scale prototype. I’ve already burned 3 hours of my projected 10 hour time cost, but if I can whip out the prototype in 2 hours, it will be time well spent as the prototype will amply demonstrate all the slack (SLACK!) in my protocol which can only lead to downstream success.

I feel 9.2% more confidant that I can pull off this caper. Yes?

STRANGEDAY –

Even for here. Not even counting the stand-up comic road race marathon up and down the Vincent Thomas Bridge – luggage off the bus accessed via a slide into the basement of the out-dated Post Office in your home town demolished 30 years ago..

For those of you who do not want to read about strangeness, please pick up your latest copy of Reader’s Digest.

The economic news – whatever it was – from China imploded the stock market, which is understandable.

“Hmmmm, I see that durable goods orders for September 2023 have slipped a peg, best sell off my entire portfolio.”

Of course, no humans are involved. The Market is driven by 42 algorithms each of them the benchmark for 203 other algorithms which in turn trigger the other 3,562 algorithms that actually cause stocks to be sold, or bought, or both. At the same time.

Forecast for Ypsilanti Saturday calls for snow, kiwi’s in NZ ripening four days ahead of predictions, Rwandan elections postponed, mass-dolphin die-off in Guam …. Last time that happened and we shorted pork bellies we made 0.3%.

Remember that payment to JohnsonArts from the Glaswegan? It too was controlled by forces outside human competence as I get an apoligetory phone message: “Um, I thought I wrote that check from the corporate account but I wrote from my personal account and so it bounced.”

Good thing I didn’t need the two fifty until twenty minutes ago….

Even so, I invest the afternoon in the Glaswegan Doggie Cenotaph Prototype (DCP).

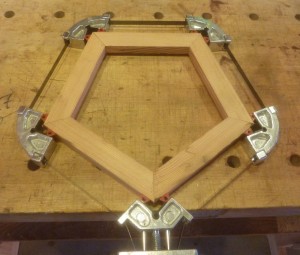

It’s a personal challenge – can I fabricate a pair of five-sided frames, the 108 degree meet angles perfect?

Turns out, I can’t. At least not today.

Rive out from one of the former front drawbridge steps the cross-sectional shapes needed for the DCP – the base ¼” greater all around in footprint that the top. Plane to the not-required-but-completely-invented-mock-dimensions, then rabbet as if for the glass from the Glaswegan.

And that was the Easy Part.

Rigged the table saw for the sliding mitre gauge, cut five of the blanks for the top at the desired angle …. And discovered that NO, I had not left the sliding mitre gauge at the angle for a pentagon, but instead at 45 degrees.

Send Supervision.

Reset.

Yet the sliding mitre gauge will not easily accommodate the short pieces the DCP requires: less than 7”. Fall back onto insufficient bandsaw cutting power.

In addition to making smoke like rubbing sticks together, it is now thumping like the steamship propeller shaft is bent.

The inside angle is 108 degrees, even knowing this does not allow me to actually MAKE two 54 degree angles…

Bend myself to adjust the sliding mitre gauge to 45 plus 9 degrees making half the meet angle of 108 degrees of a pentagon.

Except that I didn’t.

Made the angle 36 degrees without knowing it until tried to fit all five pieces.

I welcome your hatred, but you’ll have to get in line.

Reverse the mitre gauge and lam out the really, almost, approximately, close, sort of 54 degree cuts on either end of the pieces.

They fit like magic.

Bad, missing a term, the spell was canted inside out and resulted in solar implosion magic.

I’ve had days like this before where everything I did was WRONG.

Once.

Nearly burned down Hunter Mountain.

Ach Zo.

Since the bandsaw result isn’t quite right, perhaps I can finesse the angle on the disc sander. Form a 9 degree triangle which is laid against the already-set 45 degree guide and then gently shave each of the 10 meet surfaces, checking for equal length for all five pieces.

The result: Horror.

It’s an equation with 10 unknowns. There is no way known to me on how to ‘set’ a pair of angles and then benchmark these and from this benchmark adjust the other eight. Maybe there is a way, I just don’t know what it is.

And so I am reduced to trying to delicately adjust each and every one of the 10 meet surfaces with the disc sander driving toward perfect 108 degree angles. I even make a 108 degree template (which, given our tools and acumen has to embody plus or minus a degree or more, and so this expedient is chimerical at best).

The angles all seem to be 108 degrees when measured separately against the 108 degree template, and yet do not merge into the happy whole with no gaps in the joints.

Just as I’m about to put my head into the bandsaw, The Prof arrives with much needed distraction, and beer. Did I mention “beer?”

He’s fresh from the barber surgeon, has the clutch interview with MIIS next Tuesday for a job he’s not sure he wants in a position he’s sure he can’t afford to accept. The Wild Card is if his current billet at the Naval Post-Graduate School sinks under the waves, he cannot afford Not To.

Schadenfreuden about the Strangeness – told you to read Reader’s Digest….

SUCCESSDAY –

My inability to create 108 degree joints gnawed at me all night. Nobody can’t make 108 degree joints, why can’t I?

Nothing for it but hitch up the House Hippo and ride over to The Shop and Keep Trying.

Still cannot fathom why the bandsaw is balky. I’ve replaced the thrust bearing, they are running freely. The guide bushing are not too tight. The drive belt seems a bit loose, replace it. Betterment? Not really. Maybe in running the saw before I replaced the thrust bearings I fragged the blade. It’s the only thing left to replace.

But later. NOW, revisit the 54 degree angle joints. I’m close on the prototype DCP top joints; cannot I not just keep trying to adjust the angled mitre gauge?

I can, and do, and with only about three trials, gradually swiveling the gauge toe-in – Hosanna! Close enough that just a little hand sanding closes all five joints.

Then the mitre gauge leaps off the saw and crashes to the concrete, ruining the setting, so I have to replete the sneaking up on the setting process all over again for the prototype base parts.

Finally, the joints are close enough for prototype purposes, not quite as tighty-righty as the real-deal will require, but I’m close enough that only a few of the joints need finesse, rather than ALL of them.

Glue up the prototype base and top, recognizing that I didn’t rabbet with sufficient depth the top, so noted for future.

More strange than the cross-sectional shape is that I’m building a five-sided figure and only make four vertical connectors.

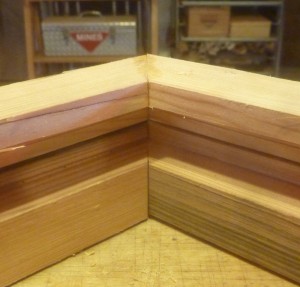

NOW – the real challenge/fun/tumult: form the complex shape of the verticals. Can I make such a shape in cross-section? The revisited, adjusted, Kentucky windage allowed for full-scale drawing seems to indicate that a 15 degree cut starts the process. And it does, and it turns out that all the rest of the cuts are made with the table saw blade straight up, except for the final dross trim where it is angled at 30 degrees.

There they are, roughed out. Except that while I’m being all proud and shit, I realized that I don’t need the four that I made. I need five. DOI!

Tomorrow, if tomorrow there be, and one more vital fabrication detail, trim 3/8” from the outside ends of the verts for the bottom meet and 3/4″ for the top so that the remainder will seat flush with the inside rabbet at the joints.

Like this. This will make for more secure dowel joinery between the verts and the top and bottom of the thing.

Like this. This will make for more secure dowel joinery between the verts and the top and bottom of the thing.

The compass of a man reaches to all directions, the horizon always limitless. Fruition takes many forms: stacking up piles of money, raising up healthy honest children, adulation, Some find satisfaction in problem solving, particularly when the problem needs solving every morning on awakening.

MOCKUPDAY –

I can finish the full-scale engineering mock-up of the DCP today. Yes. Maybe.

But before I can make the final assault, must return to yesterslack, or its equivalent to form the fifth vertical I forgot to make. And so made two so now I have six and need five. Fine.

Next – replace the bandsaw blade. Maybe I did ruin the blade before I swapped out the thrust bearings, and lo, I’ve Got My Bandsaw Back! The blade was fragged.

As if that wasn’t joy enough, unclamped the base and top of the DCP for a form and fit test. Those inside corners need to match, and lo, they were pretty durn close – close enough.

Heady.

Can now slice the ends of the verticals so that most of the post fits into the recess of the inside edges of the base and top. But not so fast.

Because I intend to dowel join the verts to the top and base, I ought drill into the ends of the verts first, in the even what I cut off overlaps the dowel holes.

This turned out not to be the case, and in retrospect, I needed NOT to dowel hole the bottoms of the verts as these can be joined to the base with screws from beneath.

Miraculously, had the vertical clearance to use the drill press to drill the dowel holes, but made one critical mistake – used the Never Used drill press stop – and was reminded just why I never use it: the thing doesn’t actually limit the drill press travel, only suggests to stop lowering the bit. Next Infrastructure Day I’m taking the bleeding thing off and throwing it at a rabid dog.

While later analysis certainly suggested the bottom of the verts to the base need not be dowel joined, the top certainly wants to be blind doweled, doesn’t it?

Zarf off the requisite (differing) amounts from a portion of the ends of the verts so that the shoulders will seat on the show surface of the base and top, then cut the dowels.

But before I lam into the dowel joinery, desire to put the feet to the base. They will lighten the look of the structure, and serve as a structural bolstering. Yes. Not maybe.

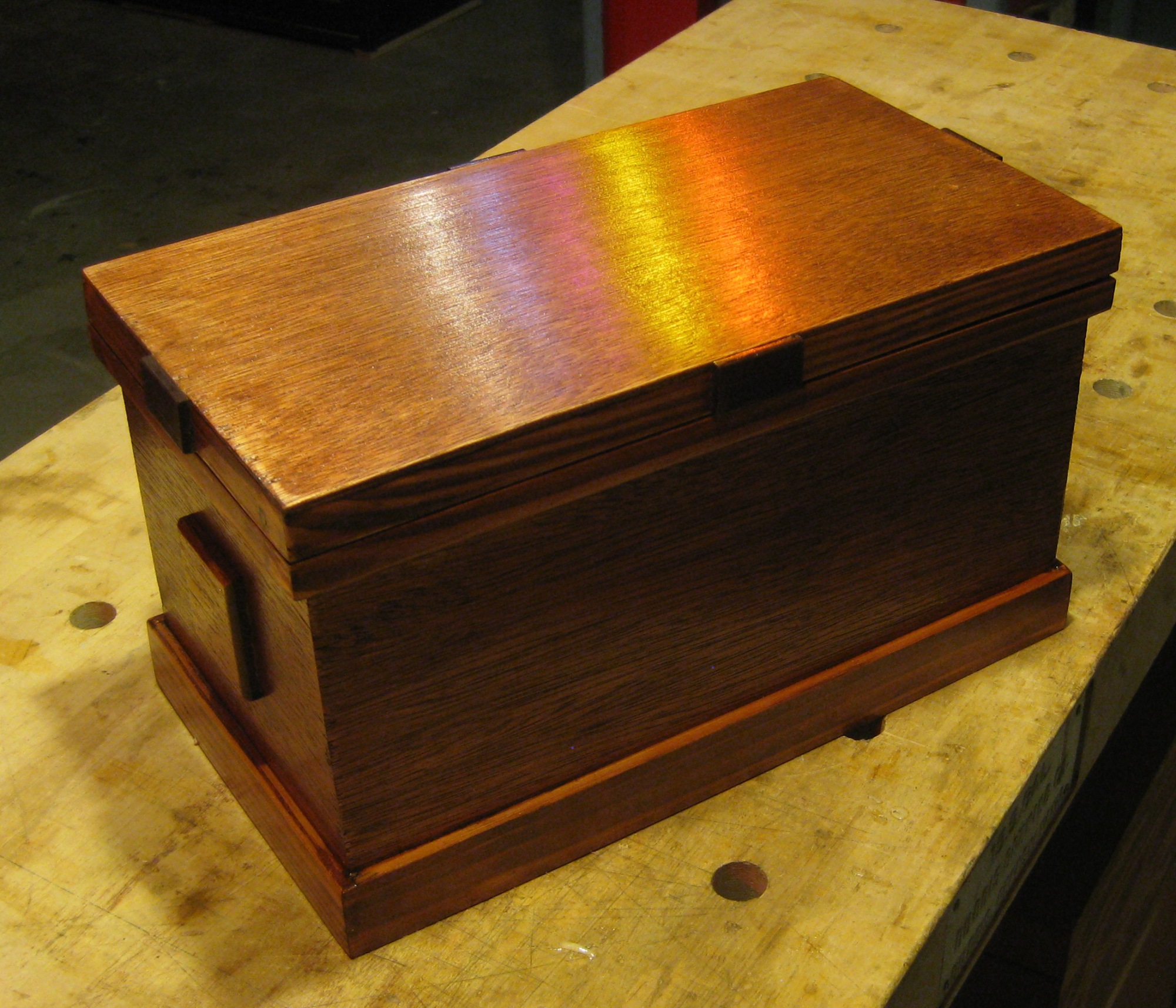

At Last, can put the thing together, and together it came, better than I had a right to.

Thanks to this prototype, I’ve sussed out most of the fabrication and assembly details. From here – once I see some cash – I can tailor this design to meet the actual glass pieces.

This Design: didn’t actually devote conscious thought to the way the verticals become the most important aspect of the project, it just happened.

Since the verts are kerfed on both sides, these kerfs match insets on the base and top, the 5 glass pieces of the sides will be held in without any need to resort to thin furring strips nailed from the inside.

The Top is slightly different, but by notching the ends of the top of the verts, similar to how the verts were cut to fit into the top recess, simply applying the top, with the top glass in place and gluing will hold it in place.

Simple, and yet all my energies went into the gross fabrication.

The planning that resulted in this design that will allow most of the Cenotaph to be assembled and then the glass inserted just materialized, as if there wasn’t any other way.

Strange. But strange good.

Except that I’ve burned 13.5 hours just making the prototype.

Project Arcturus

Project Arcturus  The Un-Chair

The Un-Chair  Travel Bar Redux

Travel Bar Redux

No comments yet.