The Hoopladrome

3 10 – Fortunately, my insouciant too-quick to cut the walnut down to a 12” wine bottle for the Ducci Traveling Bar was not the death knell of this project. Mr. Ducci responded to my question about sizes and it turns out that he will be using it for booze, and bottles of Johnny Walker no taller than 12”. Phew.

And not in time for the Blog last time was the crucial drilling of the central hole in the hexagonal top of the Hoopla Troupe Case. It would not fit into the drill press and so your artisan must needs rig a jig.

Cooked up contraption to allow center boring a hole in the top glass. It couldn’t be done before the top was put together because I couldn’t be sure just where the exact center would be…

Clutch was posing the positional drill rig atop the glass so it would not move.

Not simple.

Yet simple.

And safe and effective when immobilized as not directed.

What followed was a date with Curtis at the pre-eminent brewpub here in our little village – The Alvarado Street Brewing Company.

Brews and synopsis: Blonde, Alta, Something, and The Egyptian; and The Best Cheeseburger I have Ever Inhaled (to date).

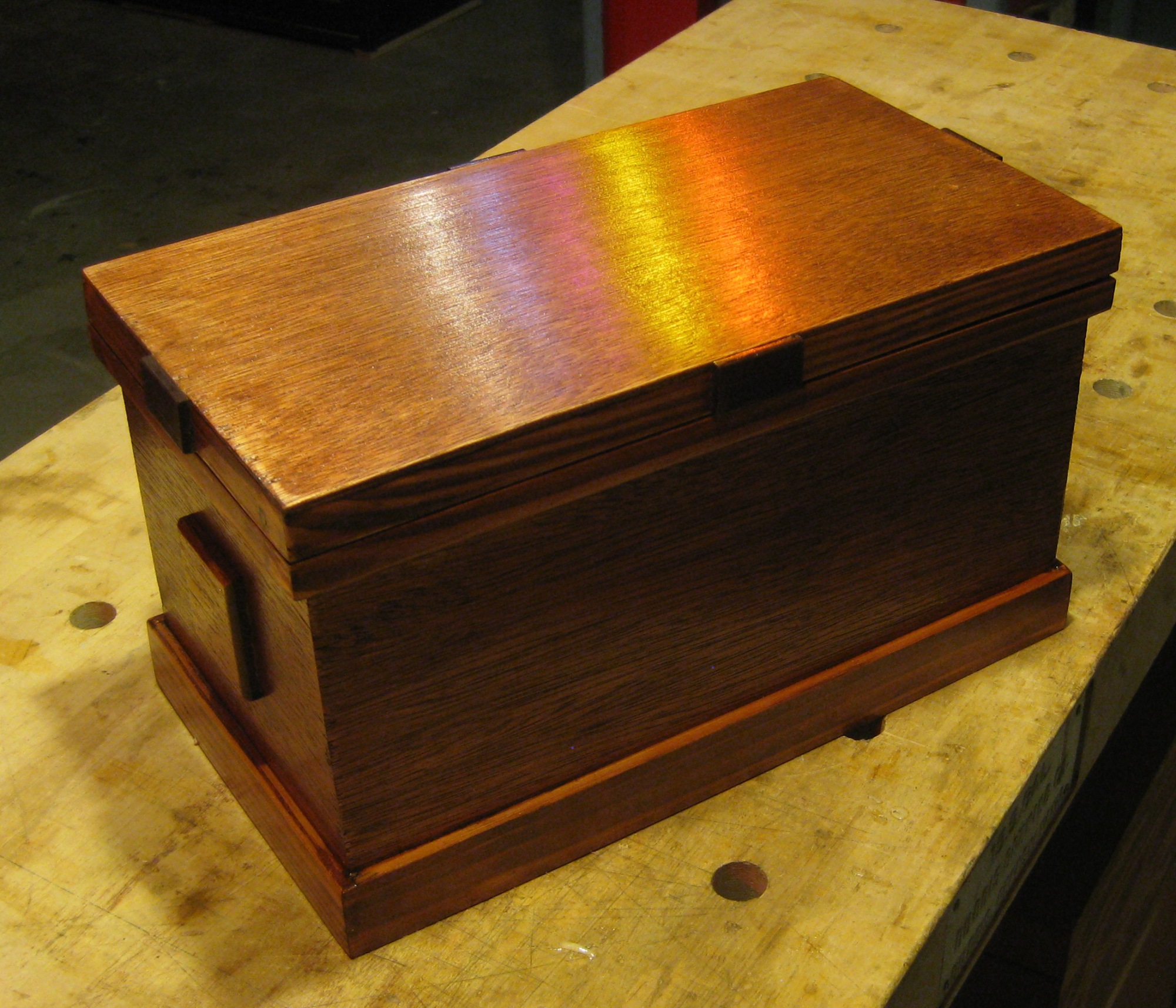

3 11 – Down the tachyon beam to The Shop and the Ducci Travel Bar.

Today’s exercise, verify that the extant parts will come together with sufficient room for the specified lucubrations.

At issue: the two dividers. I unfortunately cut the bottom and top so close (too close) to tolerance that I needed a skinnier set of internal partitions than the planned for 1/4” ply. I have 1/8” ply, but how to rout the blind kerf when my smallest router bit is a 1/4?”

How: deploy the long disused Dremel Tool router attachment.

It was a forlorn hope. I remember being disappointed with it when I first got it yaron’s ago.

After an hour setting up, the thing disappointed me again. There was so much slop that it gouged a 1/4” kerf even using a 3/16” bit.

FAK.

The rule seems to indicate that I can fit into the center well the mandated fifth of Absolute and the the two flanking bivvies will accommodate (just) the Johnny Walker twins. Will run full up test at Bins & Bottles on the morrow.

Next: dry fit.

Dry Fit Is Good.

Next next: chose a stain for the ply. Walnut seemed a little too too. So I opted for Special Walnut. There really wasn’t a perceptible difference, or was there.

Next*3: Glue up the case.

And so it was.

3 12 -It does not read like much: installed the collapsible cup shelf inside the Ducci Travel Bar door, formed 8 right angle corner protectors from brass strip, and then knocked out a handle for the case.

But it occupied all of the afternoon, mostly because I was painstakingly careful with the shelf as it narrowed to a less-than 1cm thickness near the outer end of the thing. Success.

Pre-drill the brass for upholstery nails, and then bending was less fraught with peril, even so, managed to NOT properly center the nail holes one side of the bend to the other. It’s not a bug – it’s a feature.

Finally, finessed a small chuck of oak into two bolsters and the hand grip, connected by brass strip.

Maybe.

SATURNSDAY –

Today was the 2015 inaugural tours of PBL. I had the 1030 and 1230 shows. Dr. Randal Johnson had the opening act at 0900.

He’ll do well, once he learns that no one in the room except himself wants to know everything that he knows; and a considerable body it is. He knows more about John Steinbeck in one of his eyelashes than I will ever know.

My two tours were adequate, but didn’t miss many marks and got a few laughs (no tips, though).

Ghastly weather here – temps in the upper 70’s. Terrible.

3 15 – I will not even attempt to relate the nature and effect of the worst nightmare I’ve experiences in over a year. But it made waking up panting to my current Daymare preferable.

Finish the Ducci Travel Bar?

Mayhaps.

Another four or five coats of urethane ought be applied until the wood sings, I’ll know it when I see it.

Meanwilst, I need a different lap tray for typing – the former unit is/was fine, but now that I have dual displays at the Shirk Station, the computer monitor is slightly askance and so too is the barber chair when slightly pivoted to face same. The former unit was held straight to the edge of the desk, this is not now feasible.

I figured for a pivoting slab of ply. The barber chair has a socket on the right arm into which once fit (I’m guessing) the rod under a utility tray. This same socket can be the pivot of the ply slab, once I figure out how to best affix some rod to the ply.

It turned out that a pared-down 3/8” threaded rod filled the need. All that was needed was a threaded insert and the ply braced underneath with a flat right angle bracket.

Back to the Ducci Travel Bar. Four more coats of urethane were sufficient.

Time for Final Assembly, which I’d like to tell you was simple, safe and effective. I’d like to tell you that.

All the hardware – the case locks, corner brass trim, inner appurtenances, and handle were ready.

But there’s always something.

I had kerfed the case and door sides to allow insertion of the 1/4” ply front and back. With box joints, you have an exposed end-of-kerf, like a roof gutter with no end cap, but knew that the corner brass trim was going to cover it over.

What I hadn’t anticipated was that one of the two holes that I had drilled per side of the trim to accommodate the round headed nails that would lash the trim to the case perfectly corresponded with the empty kerf. Thus, I was nailing into nothing.

The Eleventh Hour Fix? Cram some ply into the holes with glue, saw off flush, and hope for the best.

Sigh. Nothing shows, of course, except the cleat prints all over my dick where I stepped all over it.

The rest of the installations and assembly proceeded with less strum und drang.

I don’t know what to expect of Mr. Ducci’s expectations. If he expects perfection, he will be disappointed. If he expects an unique, useful, and handsome accessory that will serve him with years of pleasure, he will be satisfied.

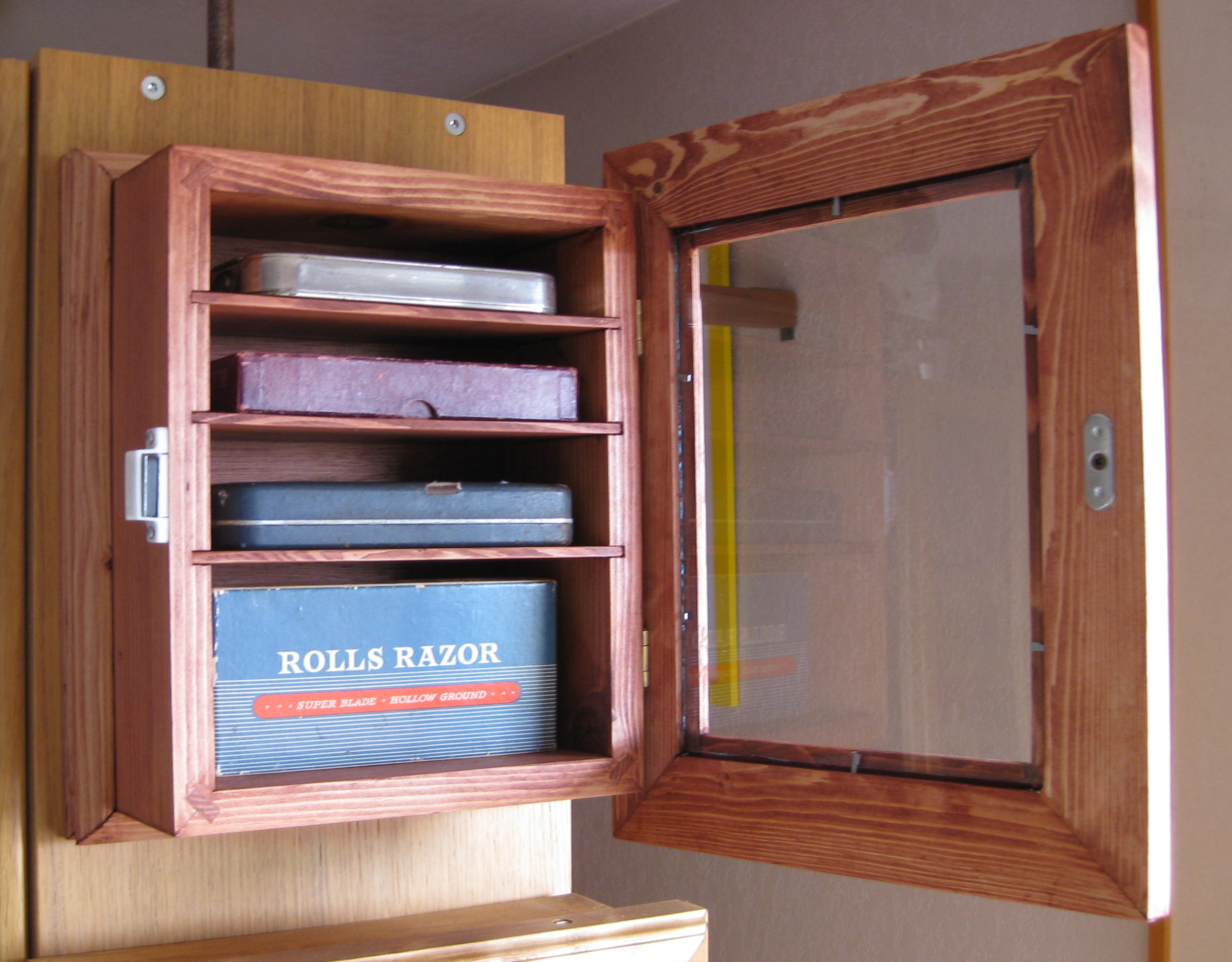

3 16 – Now that the Ducci Travel Bar is complete (although not yet purchased), I can turn my energies back to the long-neglected Hoopla Troupe Case.

In this event, painting the six panes that will form the essence of the case, or rather, the wood frames which hold the glass of the six panes. Each a different color. I chose to do this next because I’m still not clear on how I’ll fasten the lower end of the rotation driver – a 5/8” dowel – to the carousel. The top I can pin through a knob (likely it will be six-sided), but the bottom, I know not. I need something like a flange which can be ineluctably fastened to the nether end of the 5/8” dowel. I cannot imagine than given my ocean of crap …. I mean my vast storehouse of useful Dump-acquired appurtenances …. that I haven’t just the right article…

3 20 – The thrust of today’s go in The Shop was to drill all the holes that needed drilling. Into the part of the Hoopla Troupe. All the holes by which the thing will hang together with screws.

Bit a challenge aligning the top with the six panes centered, and the same for the six panes to the base.

Here is the center of the performance arena showing the holes into which fit brass rod – there are corresponding holes in the undersides of the Hoopla Troupe blocks. These short brass rods will establish the blocks on the turntable and yet allow them to be removable for play. Eh?

More holes: pre-drill for the lazy susan into the top of the base and the underside of the turntable on which the Hoopla Troupe will be arrayed.

In mid-stride – here’s Wildman!

News: not good. He is falling, backward. Not here, today, but at home, on his stairs, in the shower. It will kill him and there’s nothing I can do about it.

In second mid-stride: Wilder!

He’s scheming on some oak slats out of Napa, think 3 foot long tongue depressors dumped into the inside of wine casks to impart a flavor. Hundreds of them. Can I make something out of them?

Of course I can. All I request is that there be a buyer up front instead of us working on spec.

His two …. cripes, what ARE those two monsters …. two ‘dogs’ Napoleon and Lulu are Belgian Colon Holes or Andalusian Anus Faces and utterly untrained, spoiled, unresponsive to commands and flat out asshole ugly. He loves them.

3 21 – All efforts at The Hoopla Troupe this day were directed toward finalizing all the hardware and case parts and pre-drilling all the holes necessary when final assembly occurs, if ever. I almost made it.

Key was dry fitting the lazy susan to the case base, attaching the turntable and inserting the torque rod, and then fitting (one hopes) the case top. All will be well IF the torque rod is indeed centered on the turntable AND the hole in the glass top is within a few millimeters of center.

It was.

I was surprised.

What followed was a sequence of fabrication on both ends of the torque rod. The lower end will screw through the underside of the turntable. The upper end will receive a hexagonal knob by which the entire turntable is swiveled. This hexagonal knob will sport three sponsons for comic effect: 1/4” dowels about centimeters long with 1/2” wood spheres at their end making the thing look like a toy capstan. Somewhat.

Still open are what hides the countersunk screw holes in the case top. I opted to turn down 5/8” dowels to fit into the countersunk holes, but what will top these is TBD. It’s not Critical Path.

Next: Painting.

A LOT of painting.

3 22 – After the nightmare the daymare seemed beckoning. And it was.

Under the guidance of The Hoopla Troupe, I asked them how they best wished to display their acrobatic talents.

The Hoopla Troupe: drill for the 1/8” brass rod that will, one hopes removably affix the Hoopla Troupe themselves to the turntable – drill into the feet (mostly) of the figures, and into the turntable, then cut the 12 2 cm lengths of rod.

Test Fit is GOOD!

Now, really, I can start painting.

No, actually.

Seriously.

Paint.

I hate paint.

Not because there is anything intrinsically wrong with color.

I just am offended by covering wood with anything that does not let that woodness show.

I’ve given myself a one-time personal dispensation. The figures require this case to be circus-color gaudy.

Still …. Paint. ug.

And I thought that THAT would be all the fun I would have this day, at least until the O’boom was uncorked.

It was not.

Ring at the doorbell.

Here’s a young man who I did not recognize until I did.

It’s Vaughn Johnson, my nephew. My brother’s son.

And his wife Chris who I have never met.

And their three year old daughter Vida, who I have never seen.

And Chris’s father, Rick, on vac from South Carolina.

And Chris’s father, Rick, on vac from South Carolina.

I’m gormed.

3 23 – Paint, once the proper appurtenances to hold all the odds and sods such as the feet, capstan arms, decorative zoits was fashioned.

Much more painting in store.

Oddly, I don’t mind.

3 24 – Painting, painting, more painting and then some more painting while I paint.

And finally, glue-up of five of the six panes/sides (the sixth side will be the door).

Next: more painting, painting, and more painting. I’ve left the case base primed only as I want clear lines emanating from the corners, the locations of which will not be apparent until the six sides are mated with the base.

Onward.

LEDDAY -I’d been stewing about how to light the Hoopla Troupe Case. Sure, I have LED’s on a flexible tape; it bends easily enough front-to-back, but side-to-side: nope. This meant that I would have to mount the LED tape on the upper inside of five of the six panes/sides rather than on the underside of the top. So be it.

Next hurdle: you can trim the LED tape with scissors about every three inches, but the tiny buttons to which your artisan must solder the wires are about the size of the o in 10 point font. Can this be done.

Nothing for it but try.

It can.

Now, how to physically affix the tape to the inside of the case. I’m not relying on the pressure sensitive adhesive, particularly counting on this adhering to paint for more than about a fortnight. Can this tape be penetrated with thumb tacks in strategic locations without interrupting the circuit?

Nothing for it but try.

It can.

Major hurdle cleared.

Next, dry fit the six panes/sides to the base to determine paint lines, and paint the base AFTER seeing to the test installation of the LED’s and the wiring and switch.

Much yet to do, but it’s finally coming together.

3 26 -The consultation with Dr. Meckel went just as if I had written the script.

Almost incredulous was the kind Doctor. He read through the February NO from the Worker’s Comp Medical Oversight Board To Ixnay Any Treatment and made careful treatment to his amanuensis on how to best word the Third Appeal.

His diagnosis aligns with my own, and with that of Dr. Kantor: a partial or full knee replacement is not warranted at this time; instead what is needed is a menisectomy with a partial condroplasy and the eviction of stray bodies in the synovial fluid.

Nice shop. Big Business. Lots of money floating through the place – it looked like a space port.

The Shop: ascertaining the electronics to light the inside of the Hoopla Troupe Case.

Switch wiring is affirmed.

Conduit for the wire from underneath (a red drinking straw) to the upper inside is formed and cut to length. Prelim wiring from transformer to LED’s in interrupted by The Prof – tie me by a rope and hang me – which featured Drake’s IPA.

All Stand Down.

3 27 – Finally, a good, well better night’s sleep, no nightmares and Hallie was, if a bit thin, willing.

Hemp on the left and Webster center are temporarily distracted from those hot tomato’s the next table over…

Supersmythe collects me ’round noon for a meet with Hemp, Commodore of the Cannery Row Foundation out Carmel Valley at Jeffery’s Beanery and Dog Park.

Along with him is Steve Webster. The name sounded familiar, and it should. He and the Packard’s invented the Monterey Bay Aquarium, was instrumental in its foundation, planning and early years. He was employee #1. Astounding.

After lunch, whence we returned via Potter’s Electronics (they want to charge $79 for a LED strip power supply – the kind I get from Amazon WITH 16′ of LED for $24) to Castle Slackton Supersmythe remedies the damage he inadvertently did to Mozilla yesterslack, and in the process effaces all my bookmarks.

Me: back to painting the Hoopladrome. Supersmythe coined the name, I think it rolls better than The Hoopla Troupe Arena, so Hoopladrome it is.

Some assembly was required, and soldering, and the LED still come on.

Strange.

The Hoopladrome Complete – Finally.

It was days of layering on the six colors, driving toward a knife-edge demarcation between them. It was never reached. While I could have soldiered on, striving for that last 0.18% of perfection, I admitted defeat, or rather, surrendered to project apathy.

The final assembly was, oddly, without major travail. The only unanticipated (and should have been anticipated) partial NUTS was the degree to which the electrical switch contacts (and their wires/spade connectors dangled below the plane of the underside of the base. I couldn’t dry fit the switch because it is a pressure-interference fit, but I should have eyed up the dangle from an edge assessment.

To recover, and to prevent paddy fingers from dislodging the connections, I formed a small, open-backed metal case to shroud the connections.

I presented the Hoopladrome to Wilder, whose mother invented the Hoopla Troupe back in the 1920’s, at last Friday’s PBL – Cavalry – FOE meeting.

Done, and glad to be done.

If I were ever to do such a whimsy again, I’d consider installing a clock drive mechanism to spin the turntable, and/or some music.

But I’m not likely to ever see something on the quirky level of the Hoopla Troupe again…

But I’m not likely to ever see something on the quirky level of the Hoopla Troupe again…

His Father’s House

His Father’s House  Kelly’s Other Tool Kit

Kelly’s Other Tool Kit  The Hoopladrome

The Hoopladrome

No comments yet.