Jacket Slackit

25 minute micro-rike, all systems nominal. This followed by watching my financial portfolio implode.

25 minute micro-rike, all systems nominal. This followed by watching my financial portfolio implode.

And then, I was cheered by the arrival of Doggle, here for a five day stay whilst the Main Pack is off to the East Coast.

INTHERIGHT –

That was the name of the sextet of feature films I developed whilst asleep. I can feel the episodes more than I can describe them, particularly the later four. The first starts out at a mining operation where there are two misfits, probably one the firm accountant, and the other the chemist who is absent minded to the point of danger to himself, walks in front of a giant dump truck which has to scream to a halt and in doing so chips from the load fly. The Chemist picks one up, oblivious to the opprobrium of the driver, and instantly recognizes fossil traces of a long-suspected but never proven, now extinct, but supposed alternate branch of the carbon form of life. From here, the plot spins around their surreptitious siphoning some of the mining companies cash flow to engage and hire talented, young thinkers whose research and development discover the flaws of the extinct proto-carbon life, and secrets yet unknown. This nexus of inquiry, discovery and elaboration on the exhumed DNA leads to the establishment of a collegium-like R&D center which fosters beyond-the-beyond thinking, experimentation, and invention. Oh, and just forward enough in the future, say 2030, to be near, yet far enough to allow the writer some latitude ….

End of Episode One.

Like I wrote, I can feel the plot elements of 2-6 more than I can articulate them.

Woke up thinking, “I can’t write this, it’s already 6 movies, I’d be plagiarizing …. oh, wait, there aren’t any movies. Yet.

Yet another Doggle Day here at Johnson’s Mutt Motel where the only guest is escorted out to the garden for her 7 AM business.

Later, our business takes us to the uncommonly, for 0830, crowded TJ’s for pre-holiday beverages, then to 7-11 where to deposit my princely check from SPAR for the assembly of two file cabinets and a desk, and a 140 mile round trip = $38.83.

Onward to Dumpward where the joint was SRO – early Kwansmasnukkah Shopping for barrel rings, defunct windows, and rusty BBQ grills. Nothing on the Toxic Table for me. No shellac, alas.

Grocery Cheaplet offers improved possibilities, including a half-off hunk of NY Strip Steak for the grill. In sum – provision for the next few days so that no motor-foray amid the chaos is necessary.

Nice Plan.

The Prof and fam are off north to the in-laws, having the house tented while away. Here in the Nanny State, you just can’t turn off the gas, PG&E has to come by, turn off the gas and actually remove part of the delivery pipe. Naturally, a return visit is mandated to undo the Nannification.

Here’s where I come in. I’m on call Saturday when the gas fitters are most likely to undo the chin wiping, nose blowing and diaper changing and so I (and Muttski, of course) have need to motor over to The Prof’s estate, walk through the likely procedure and get his keys.

And find the location of his garage refrigerator.

Getting there and getting back to Castle Slackton is no harm, no foul. There’s no current project on the workbench, so maybe some housekeeping is in order. Stow some wood, re-allocate prime real estate and figure out just why that fluorescent OPEN sign in the Monk’s Cell isn’t.

It’s a failed ballast, whatever that is. This necessitates another trek All The Way Into ACE Hardware for a $3.03 replacement, but it was nice to see Norm and Tim again.

Once back within the Castle precincts could almost predict a few days of solace. And after the market performance of my one, last rope of fungability, I need it.

DDAY –

D for depression, poor Muttski misses her Pack, I’ve seen this most times she’s been here, and typically 48 hours into her purgatory.

But that didn’t come on until later in the day. Of the early morning, I’m stretching out on the Slack Deck for the rike when Muttski butt’s me, positions herself just so that while I’m splay-legged on the planks her tail whips my face. It was her job to cheer me up.

I leave her to stew while I have a quick micro-rike adding in a hill and a couple more blocks.

To Home and The Shop where no major projects are on the bench. Knock together out of scrap a small magnetic backed perch for the kitchen cheaters; replace a disc sanding pad, organize a new home for the bandsaw 45 mitre gauge; distribute some syringes into a metal cabinet and lose the cardboard box. Ever my goal: Have No Cardboard Boxes. Years away.

During Happy Hours, Yutzski yips and yaps to the outside. No one on the Castle approaches so I let loose the pooch. Offending Intruder: UPS van across the street, something about those trucks….

TURKEYDAY –

Marie Callender’s Chicken Pot Pie easily trumps Trader Joe’s Turkey Pot Pie, without even loosening its tie or taking off its street shoes.

BLACKDAY –

As in black-legged deer tick day. That ‘bean’ I found on my duvet yesterday morning after the customary Dawn Doggle Scratchings had legs. Eight of them. As if that was not squicky enough, a little research shows that this legged ‘bean’ is a blood engorged Ixodes pacificus, the black-legged deer tick which is the prime vector here on the Left Coast of Lyme’s Disease.

With this good news, I load up Muttski and tote her out to 99 Rancho where the cruise up the Valley is augmented by a Jeep and Prius who want the trailing motorist to more enjoy the drive by economically lowering the speed thus giving the tail end charlie greater languor so as to savor each and every furlong.

At 99 Rancho the furry parcel is accepted by the daughter’s beau who is looking after the place whilst the fam is in NY. Yutzski, we hardly knew ye.

The traipse back down the Valley was nearly, but not quite, unsullied by Asian grandmothers driving a tow truck pulling a Volvo station wagon.

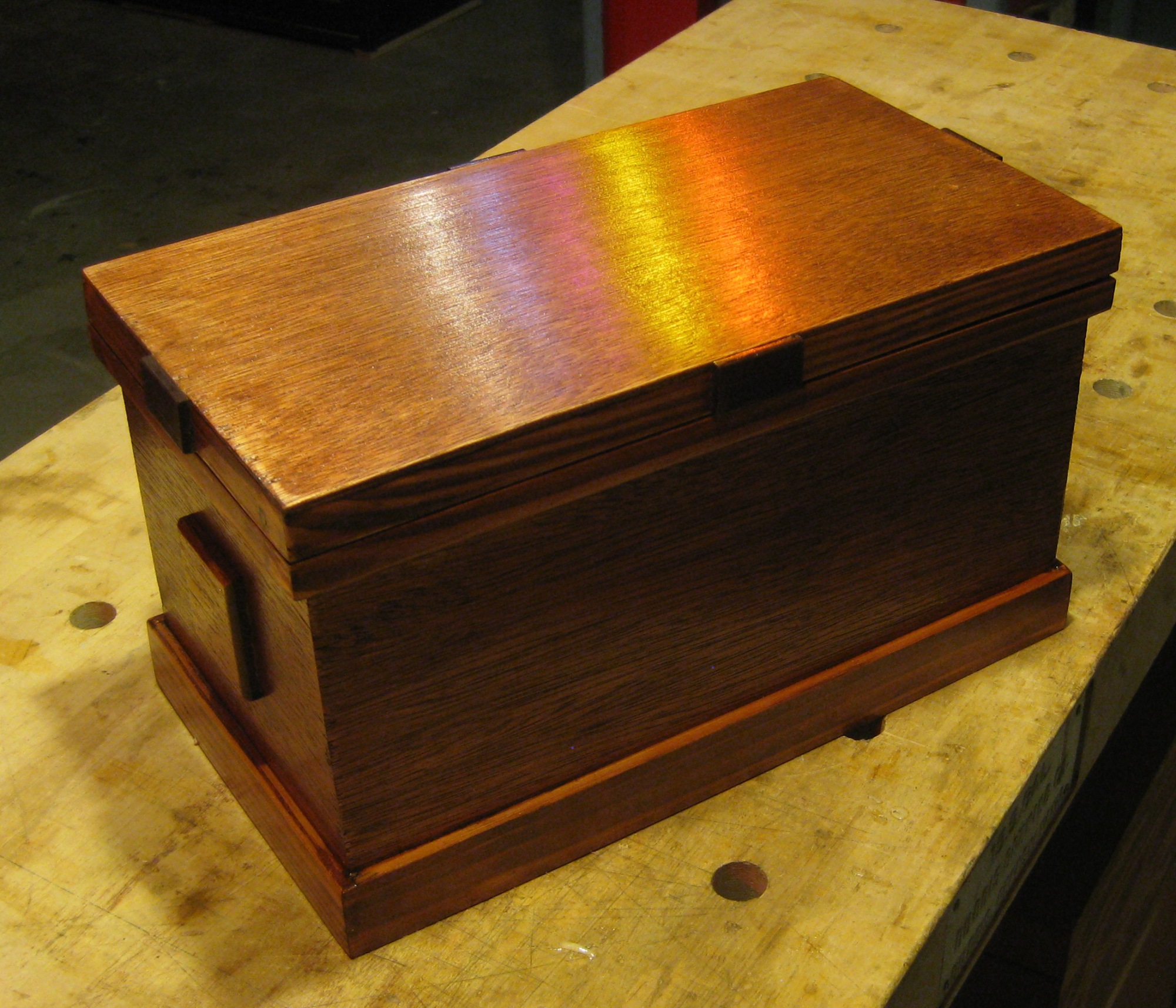

Then, to the Bucolla Gallery in Carmel where I wanted to show the artist my progress, such as it is, in forming double 45 joints, and give her Test Boxes #1 and # 5 as evidence.

There’s nothing stirring in the commission realm for me, but best to keep nagging …. I mean maintain the JohnsonArts brand awareness.

DUSTDAY –

At a creative lull, no projects on the workbench, and there should be at least three.

The wee hours of the Midnight Study Hall produced, on the plus side, an urge to revisit drawer making. The recent File Cabinet project left me feeling underwhelmed with my drawer fitting acumen. Thus, today’s intention to lam out some wood sufficient for five or six drawers, and plenty of spares.

Plenty of redwood planks salvaged from Wildman’s former digs on 7th Street, so I cut them to two lengths, jointed one side, squared the ends, and then re-sawed them to double the drawer parts.

Much planing – too much planing – to get all the parts to a uniform thickness, which is about 9/16”.

Separated the lot into drawer parts, and practice parts. Practice? Practice using one of my long neglected locking mitre bits for the router table.

Here’s a member of my router bit arsenal by Katana. I even have set up blocks that show you the proper height setting …. If you’re using ½” or ¾” thick stock. Which I am not.

Thus, it is left to the student to swag both the fence position and the bit height. I’ve been down this road before, and the insufferable results are the reason why the bit has grown moss.

The one bit is designed to cut both sides of the locking mitre, but to do so requires that the drawer sides are run flat to the table and the drawer front and back are run edgewise, standing up against the fence. In spite of near-heroic efforts, I’ve never been able to consistently, safely, and accurately run boards upended edgewise.

That’s the main reason why I invested in a horizontal router table; what must be run standing up on a typical, vertically oriented router table can be run laying flat on a horizontal router table.

There’s only one snag: I’ve only one Katana bit.

Setting the bit height and depth of fence is an equation with two unknowns – not straightforward to solve. BUT, when you have to guess that the bit is set properly in the vertical router table, and then take it out to move it to the horizontal router table, you double the amount of unknowns in the equation.

Solution – buy another of the same bit. That way I can jigger the settings of both at the same time.

It’s a fifty dollar solution, but no sales tax and free shipping from MLCS. This is done.

What is not yet done is the call from PG&E.

The Prof and his family have spent the Tday holidays in Oregon with family. The away time presented an opportunity to fumigate the house as a cautionary measure against termites due to the recently completed renovations. It seems necessary that PG&E play a staring role in this drama. Not only is the gas turned off at the line, they actually disconnect the line. Thus they have to come back after the circus tent is removed to reconnect and make sure all the appliances are up to snuff.

Since The Prof is out of pocket, the supervisory role in the return of PG&E falls to me.

At the Borer Manse was tempted by the well stocked beer refrigerator and the firepit with ample stockpiles, but I abjured.

It all worked out in the best-hoped-for scenario. I get a call from Kathi about 3:30 who will be at The Prof’s estate in 20 minutes. I’m there in 10.

There’s an elaborate kabuki reconnecting the meter using wrenches bigger than Kathi’s femur, then an appliance-by-appliance walk through and test verification for each. I ask Kathi, “Why is PG&E even involved in this fumigation effort?”

“To keep their gas from mixing with our gas.”

“But there’s a shut off valve right there.”

“There might be a by-pass.”

If I read the tarot cards right, houses have blown up during fumigation when the gas was thought to be turned off but wasn’t, collected inside the tent and some errant spark ignited an explosion. Thus the meter and feed disconnection. I reckon.

Once the line is restored, we enjoy resuscitating the range, dryer (which talks), the hot water heater (the primitive American version that rather than heating water on demand, stores a tank full), and the furnace.

Attempts to check the gas fireplace fail mostly on the strength that it is not a gas fireplace. All else is well, except for the phone call Kathi gets in mid-stride: a helpful Seaside neighbor has found her dogs roaming free on the streets. So here’s the better side of PG&E working purposefully in restoring The Prof’s happy home to consumptive coziness when all the while she’s worried about her errant pooches.

We all have our problems ….

SDAY –

The creative lull is over, although one could argue the products of last night’s Midnight Study Hall might have been better left unthought.

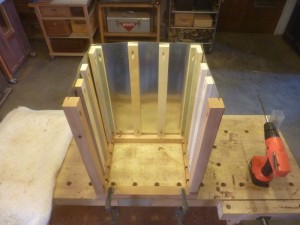

A cabinet for the drawers on which I need practice, sheathed in sheet metal sides, top and back.

A Real Guy would likely build the stick frame of the cabinet first, then cut and shape the sheet metal. But since I didn’t know how or IF I could flatten tightly rolled 32 gauge, I started there. As to the how to flatten a roll of metal, here, it is badly. But deployed the Heroic Pexto sheet metal brake and made the two bends.

The upside down U-shape will nestle into kerfs made in the stick frame.

To The Frame.

Wanted to use the wenge as I want a very dark tone on the cabinet to contrast with the sheen of the metal, but since this is a prototype, best not use the $18 board feet lumber, and besides, there wasn’t quite enough footage.

Thus – western red cedar of which I have several six foot lengths in a 4 cm square cross section.

After slicing off the chamfered corners, sized it down to about 3.8, the planed all the pieces to a square CX.

Now the fun begins.

As I’m building the cabinet to fit already bent metal, I have to form the frame to match that metal. Complications immediate ensue as I meant to butt join all the joints, but the kerf in which the metal edges will nestle cannot be hidden in joints of this manner, at least on the front and back of the case. So, opted to 45 join the upper case, front and back and butt join the case bottom.

Wrong.

If I want to indent the drawers, I need a rabbet around the front face. This rabbet will gap on the front.

Unless I do not indent the drawers.

Or, craft blind rabbets on the two sides, the chisel out for the lower ends where the butt joint of the bottom meets the sides.

Yes, I looked at 45’ing the bottom joints, but alas, I’d rough cut the bottom spans too short (although with plenty to spare for butt joints) for mitres.

So, I’m locked into either NOT indenting the drawer faces, or performing some hand surgery.

Leaning toward the latter. It’s cedar, it’s easy to work.

At this decision point, made the decision to forgo any more fretting on the Not Full Metal Jacket Project and turn to making a jig for the horizontal router table.

I’ll want/need this cope sled when I get that second locking miter bit from MLCS, as well as for future rail and stile fabrication.

The Sled: it’s a simple platform of plywood that slides across the table guided by a slat that fits snugly into the T-track I put into the table surface yarons ago.

I know, I know, T-track isn’t intended for use as a guide rail for applications such as this. Hang me.

Once that slat was formed to snuggly fit into the T-track, and made flush with the table surface, I could attach it to the ply platform.

This was the easy part.

The critical and not-so-easy part is affixing a cross piece to the platform exactly perpendicular to the axis of the router bit. This cross piece is the support for the work pieces one wishes to run against the router bit. The slightest deviation off perpendicular will result in a malformed, catawampus rout profile.

What I did was use Grandpa Swope’s square against the metal frame of the router table – not the fence – to eye up the cross piece position. Then I drilled oversize holes for the screws intended to lash the cross piece to the ply platform. This allows for wiggle so that the cross piece can be loosely acquainted with the platform, brought to square with the square, then firmly screwed tight. And so it was, or seemed to be, as far as my feeble eyesight could tell.

The real telling will be in making that first test joint. Send hope.

Whilst hoping for something, there’s a clamor on the Castle drawbridge. The torches are lit, the guard is deployed and in register to the cry the call back is “I’m Joseph!”

Joseph the travel agent once here years ago, no I don’t remember him, but he has the Castle Pass and is so admitted to the West Precinct.

3FOR4DAY –

Three went my way.

I crawl out of the pool, walk the deck to the locker room but have forgotten my soap and towel I the locker. This happens three times, it’s like one of the dreams where ….. oh, it was a dream. And I’m not even going to relate how Professor Curtis is giving us a 55 page essay test, and he’s in a pineapple costume.

The Oh for 1 was my lifeline on the Stock Market when continues to ebb, and with it, my survival.

Better was my consultation with our Groundskeeper, who when shown the flood automatic valve vault for the irrigation system claims he can find the leak and fix it, but not until Saturday.

Anon, time for my appointment at the DMV. Credit card charged 10/22 for the truck registration; no documentation in the mail. Multiple calls to DMV – which has a curious hold system you chose a ‘virtual hold,’ punch in your phone number and hang up; then, when a human is available, they call you back – revealed that no, a replacement set of documentation and sticker will not be sent me. I’ll have to visit the local office.

Naturally, at 3:00 its packed, the line to the front door. But then I notice the “Appointments Only” queue only three deep. I’m at the counter in two minutes, fill out a simple form attesting to my non-receipt of the documentation and given my wait number AO26. There are maybe 100 people whose lives are ebbing away as I take a few photos and don’t even have time to complete that when AO26 is directed to Window 12. Caribbean woman by the lilt of her accent. I present my forms and am immediately issued the replacement documents. I’m in and out of there in 10 minutes. I was amazed.

Now, can Bohr Heating and Sheetmetal be consulted?

Why? It is clear from my feeble effort to flatten that role of 32 gauge sheet metal that I need to call in the pro’s, or at least solicit their guidance.

I figured that they’d have a reverse roller, and they did, and even volunteered to use it for me. It’s a set of three rollers, two opposed that feed the sheet and one off-set to reverse the roll bend. Worked beautifully. My offer to pay was graciously declined. 3 for 4.

Now, that benighted 3/4 Metal Jacket takes on a new sheen. Now, I can build the cabinet with more facility and THEN fit the metal to the cabinet rather than the bass-ackwards way I’d started Sunday. And with smoother metal.

There’s only one assembly known unknown, but I’ll work it out and it need not be elaborated upon here – the pictures in the end will show the issue…

DRAWERDAY –

Not, as it turned out, but for a substantive reason.

The Not Micro-rike went well, 40 minutes and to the top of Huckleberry Hill, nearly. Five dogs, three cats greeted, twelve crows harried.

To The Shop.

Reverse rolled the roll of 32 gauge sheet metal in the hopes that when unrolled, it will evince little to no curve.

Now, to the Half Metal Jacket Cabinet. While not immediate to The Critical Path, cut the kerfed, show bottom sides and the 10 internal front-to-back connectors to 49.5 cm. Simply wanted to have the complete set of parts ready. These connectors, which will not show, can be 3.5 cm width ¾” ply. Not only can they be, they now are. The intention is to pocket hole join everything.

This is the multiple cut to the same length jig on the table saw with the once useless noids now earning their slack.

None of this proceeded apace, however. I’ve a jerry built fence attachment for the table saw mitre gauge with a slot and a block with two carriage bolts. This attachment allows me to set the block and then cut repeats on the same length. Except that the cheap Harbor Freight wing nuts have not nuts, meaning that the wings break off. All of them. Every wing. And so had to MAKE ‘wing nuts’ as none of my jig knobs are the requisite 5/8 NC 18 of the bolts on the sliding block.

Happily – and I am the happiest person I know – I have FINALLY found a use for the ‘clevis’ I’ve removed from some magnets. Clevii designed so that you could loop a rope through and drop the magnet into the marina where you dropped your screwdriver. Only had to thread out the existing hole. Voila.

Now returned to the Critical Path, knocked out the bottoms sides and the 10 connectors.

Fine. Can now rabbet the face frame, a rabbet into which will nestle the drawer fronts, and since the drawer fronts will be 90 year old fir door panels (currently, with 90 year old varnish and grime, at 5/8”) will be planed down to 1/2”, I so set the table saw to make the 0.5 x 0.5 rabbet.

Mitre at 45 each ends of the four pieces of the face frame and fortunately stopped myself before gluing it up. I need to dado the inside of the frame for the drawer runners.

And I STILL am perplexed on how to lay out these dadoes’.

I’ve 26 cm clearance top to bottom inside the face frame once glued up. That seems to suggest that the drawers need each to be no more than 6 cm in height. If that’s the case, and we assume that the drawers will be dadoe’d in the center of each side to slid on the runners, how the heck does a guy (not Real) measure this out?

I took the elementary school way: I trimmed the redwood drawer spares down to 6 cm, marked the 3 cm center, then laid them into half the face frame. This did indeed show me where the center of the runners out to be, but how does this allow me to make the drawer faces all the same size.

I doooonnn’ttt knnnooww.

And then I did the proper thing here for JohnsonArts, I stopped.

I cannot give this to The Prof because I would only be trying to console myself for all my mistakes. It is Firewood.

Picked up the discarded not drawers from the File Cab Project, pulled out of the trash bin really, and drove them mercilessly toward a sort of three-tier In Out Pending arrangement intended as a gift for The Prof. The Prof who arrives just as I’m about to lam the junk together with ½” aluminum angle.

He leaves all too soon and I crack the whip on whipping the junk into shape.

Wasted effort. It’s just as wretched as even before the not-drawers were recovered from the trash bin. Sometimes I just don’t understand me.

PROGRESSDAY –

Not with extricating meself from the fatal, financial flat spin, but with important matters, such as wood.

As it was provisioning day, set forth, in the early morning chill for overnight was about as cold as it gets here, not North Dakota or even Pennslobovia cold, but into the 30’s cold, toward and to TJ’s for the pre-weekend O’boom rations.

Secured, motored out to The Dump where I donated a two-tier cart bought there yarons ago. Felt 0.362% better about myself in lightening the load on the physical plant, but this in no way compensated for the inability to put on my driving gloves due to the swollen pinky and middle joint of The Finger. Been that way for months. I assumed it was arthritis, but it seems to be fluid build up. Spider Bite? Lyme’s Disease?

Unease follows the cart donation at The Dump. Crap Slump.

Better pickin’s at Grocery Cheaplet where Torento’s Italian Hot Sausage can be had for $2.39/lb and Monterey Farms Cheddar for $2.50/lb. Cause wallet leakage, but within operational parameters.

Finally, Ka-Nob Hill for Palermo rolls, oranges, grapes and gracknoids of opportunity.

With these necessary protocols seen to, it becomes time for The Shop.

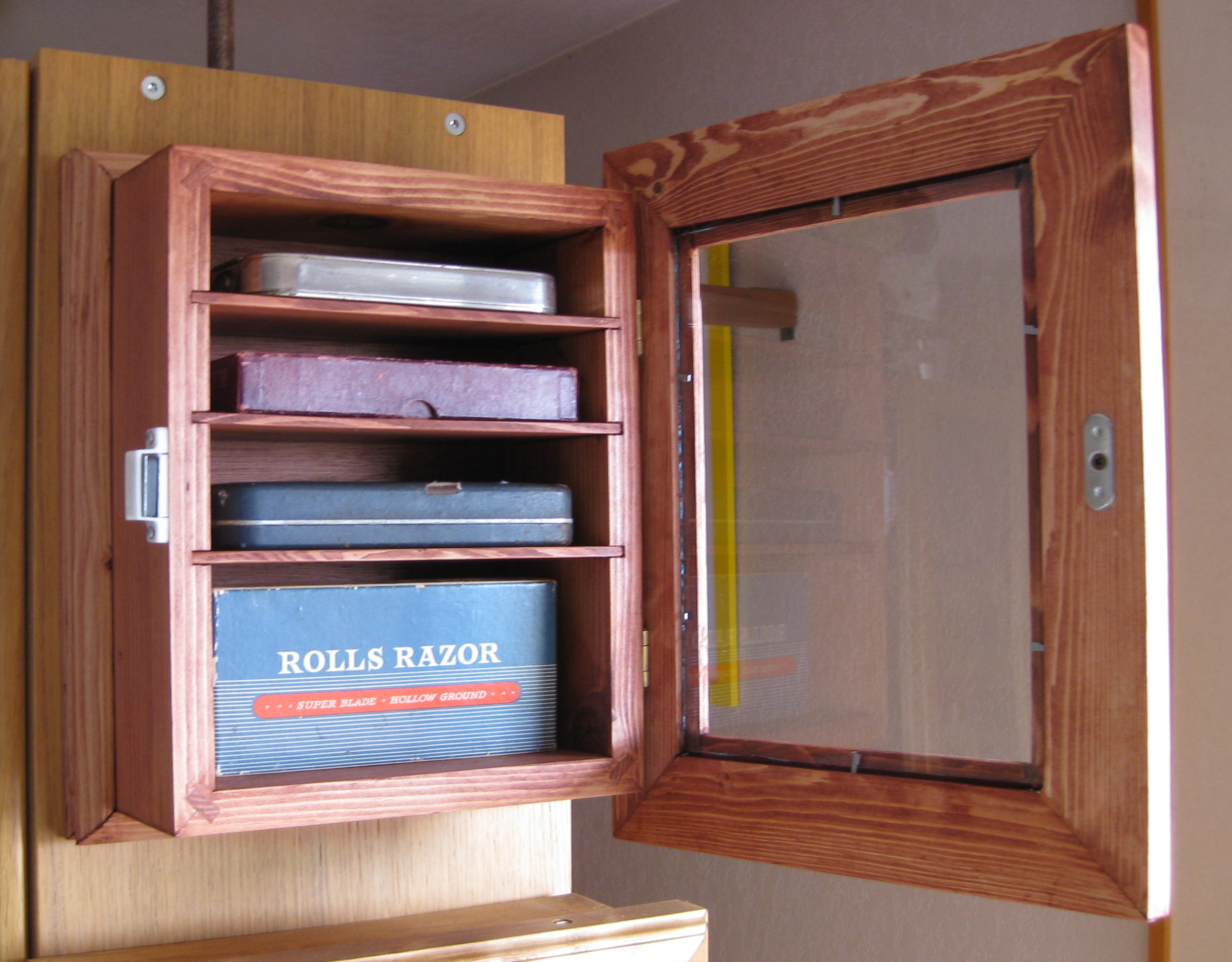

Half Metal Jacket Project – The Drawers.

A Real Guy knows how to lay out the drawer slides without even taking off his street shoes. I’m not that Guy.

Midnight Study Hall suggested that I should form the drawer fronts, then see where these lay against the cabinet front. This ought indicate to the artisan where the drawer sides ought be positioned.

And so it did. My mandate was to make all four drawer fronts the same sized. Because of this, and the circumferential rabbet about the inside of the face frame, the two center drawers may remain at 6 cm height, but the top and bottom drawers must be cut back to 5 cm. So it shall be.

Centered the drawer slide dado on the centers of the drawer faces. Too much tear out even though I deployed a backing fence on the mitre guide. Arrrr!

Now that the dado’s for the slides are formed, can form the slides. Lam out two lengths of 2 cm thick pine. Slice out 1.5 cm thicknesses, then plane these down to just fit into the dados. Significant Unknown arises: as these drawer slides are 55 cm long, supported only in the dado’s front and back of the case, will they sag in the middle and impede drawer slidage?

Onward.

Have 92.53% confidence that gluing up the face and the back of the cabinet is the proper next step. This is done.

The next step on the Critical Path is drill the pocket holes for all such parts as require them. Them that requires same are the 8 front-to-back connectors; the two to go into the two upper corners a joined L-shape, all from ¾” ply.

Pocket Hole Joinery – Elmer Approved.

BENTDAY –

Lucid dream in the frostiness of the morning – I’m searching for that English class I’ve been skipping all term …. It’s in THIS building, somewhere. Here? Prof asking one of the students to tell him about her extra-terrestrial encounter. Nope. Here? Hoagies being delivered, guy walks right up to me and pushes me out the door with his hand on my face. I make it three steps before turning, opening the door, finding the guy and pushing HIM away by his face. Then I spit into my hand half a dozen molars. Cripes! This is just like all those ….. Aha! THIS only happens in dreams! I can FLY! I levitate about the building cautioning myself not to be overly select as I know this dream won’t last as long as I’d like and soon enough here’s a suitable partner for some … shall we say, down-to-earth action.

In Shop Action – it’s the Half Metal Jacket Cabinet. Specifically, unclamp the cabinet front and back faces, sand where necessary, then stain with red mahogany. The stain imparts a luxurious tone to the fir, will look even better when I lam on the top coats, whether shellac or Wildman’s Special Elixir is as of yet unknown.

And writing of unknowns, yesterslack’s concern that the 53 cm span of the drawer slides drew the attention of our Design Committee this day. A report from the sub-Committee for Always Over-engineering recommended not one but two stanchions to better support the span of the drawer slides. I looked over the recommendations and in spite of the Cassandrian predictions, ixnayed them. The drawer slides have sufficient heft and most significantly, they never will be loaded full-on directly in the center of the span.

So much for the easy part.

Now, must cut from the recently almost flattened – Thanks to Bohr Heating and Sheet metal to precisely 104 cm length. My Harbor Damaged Freight angle grinder with a cut-off wheel does the job nicely. Now, I mark the 31.6 cm lines in from both ends, leaving a 40.6 span between.

Turn to the Mighty PEXTO brake – it’s my hero.

Does the metal fit the kerfs in the front and rear face?

No.

For two reasons.

1 – the 31.6 side length was based upon the total length of the kerf in the front and back faces but did NOT account for the shortening effect when the bottom connectors would be joined. It’s too long by about 5 cm.

2 – the center span – side-to-side on top missed by about 4 mm. Rats.

Cannot imagine how I can salvage the existing piece. Sure, I can cut the errant too long sides back by the 5 cm, but can I re-bend what is already bent?

Once more summoning the Mighty PEXTO, I work one of the bends back into the thing and reverse the bend.

It’s terrible, it’s now more of a crimp than a reverse bend.

Must Resort To Caveman Wisdom.

Put the metal on the workbench crimp up and start hammering away on it, gently but repetitively. And by all the Gods, it works. Not too bad ….

I can now rebend the piece, which I do and the side-to-side fit is GOOD!]

There only remains slicing the 5 cm off either side and test the fit. Fit is GOOD!

Technique is BAD! Krenov said that once you’re working with the parts, forget about the measurement and numbers, and work with the parts.

There’s nothing stopping me now from assembling the cabinet. Except that it’s 4 o’clock and quitting time, and time to get the truck back into the garage as there exists the possibility of rain. We should be so lucky. Looks like we’re to be cheated once more…. Send cloud seeds.

JOBDAY –

Yes, you read that right.

But I had an hour before my appointment out Fort Ord and so I set to, to assemble the Half Metal Jacket Cab.

First it was connive a solid, no-fooling two corners into which the bottom sides would nestle before and during the pocket hole screwing. This was effected with some aluminum angle, clamped both ways.

With the bottom sides in, it was time to put the metal to the cabinet. It slid in like a high school senior with a pocket full of date rape, although I could have used another 2mm of top length on the metal as there is now an unalterable gap of that glaring magnitude on one top corner.

Half Metal Jacket Cabinet halfway assembled with the front-to-back connectors pocket hole screwed to the back face frame.

From here, it was screw in the front-to-back connectors; 2 on each side, one each in the top corners, and two across the top.

Still, there are gaps where the metal isn’t quite flat. These gaps were ameliorated – thanks to Joe Gernand’s suggestion, and this suggestion was about how to ‘float’ panels inside a frame – by jamming into the gap on the inside some 3/32 weatherproofing, squeezable, hollow tube used to lash screens into a frame. Worked well enough.

And writing of work, of to Fort Ord to assemble a file cabinet and a chair.

The address isn’t one of the newer billets, but would have been considered upscale for NCO’s during the Eisenhower Administration.

Three human denizens – two near invalids and what I took to be their guardian angel/caregiver – exist within. The guy used a walker, the dog is near comatose, and the genetic female shops for muumuu’s at Tarp’s R Us.

The file cabinet is about the cheapest piece of goods you can trade a three-legged goat for, but the chair is suitable for church pastorates and rental car back offices but utterly the wrong choice, as it’s on five casters, for duty on dirigibles, and muumuu better not ever try it’s structural strength.

None of these observations had any bearing on my assembly tasks. Ignoring (trying) the cigarette smoke and stripping down to my jock strap due to the insufferable furnace output (well, not really down that far) I set to on the file cabinet.

Once the Independent Merchandiser is familiar with the hardware and the basic assembly scenarios of furnitures such as these, the chief challenge is identifying all the parts, which are, in my short experience, not always as well marked as they could be. But this recognition comes with experience and time.

It takes me about an hour to do the file cabinet, all the while Paul sits watching, saying nothing as if he was taking a cattle prod to the forehead every half hour. And I wasn’t far wrong. The genetic female was, in the later time I was finishing the file cabinet and knocking out the chair, which took, thanks to my excellent training by Dave Lando, about 6 minutes, was counting and apportioning the 40 pills a day – yes I heard that number – the 40 pills a day they both each take.

It takes me about an hour to do the file cabinet, all the while Paul sits watching, saying nothing as if he was taking a cattle prod to the forehead every half hour. And I wasn’t far wrong. The genetic female was, in the later time I was finishing the file cabinet and knocking out the chair, which took, thanks to my excellent training by Dave Lando, about 6 minutes, was counting and apportioning the 40 pills a day – yes I heard that number – the 40 pills a day they both each take.

I get the sense that she was a hot tomato back during the Kennedy Administration, what happens to people?

I’m done to their satisfaction, in so far as the signed paperwork will forever indicate, and out of this smoky prescript hell in 80 minutes. SPAR does me $25/hour for the time. Not bad, if a guy could get more of the rate and less of the cattle prod.

Man At Shirk …. or Not

Man At Shirk …. or Not  The Mystery Syringe

The Mystery Syringe  Contrast Flat File

Contrast Flat File

No comments yet.