Shape Shaping

The western window wasn’t open, so why the art gallery shopping mall Vegas shifting scene nightmare?

The western window wasn’t open, so why the art gallery shopping mall Vegas shifting scene nightmare?

It was to be the first day off for a week, and then it wasn’t.

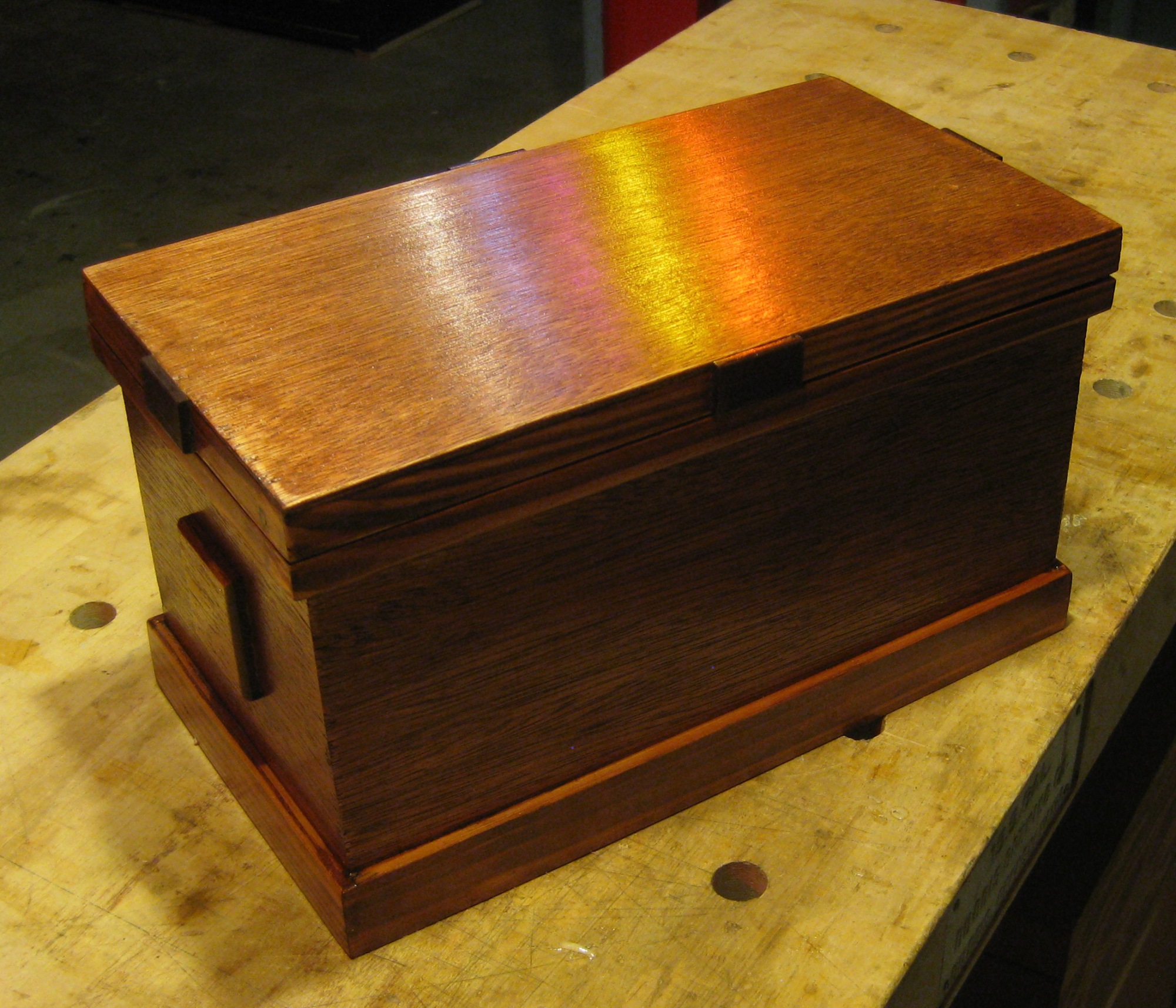

The Borer Crate can be finished this day. I told him yesterslack it would only take another hour.

I lied.

It took three.

Tasks:

Create and install a pair of handles, one each end of the short sides, handles only Magilla Gorilla can reach.

Sand the mis-aligned (Say NOTHING) lid and base to a better meet.

Blind rivet the lid/hinge to the base.

Install the front latches.

Create a stencil and spray paint on the lid: “NO STEP.”

Nail to the front a GE label removed from a nuclear reactor ceiling lamp.

Re-install (move the holes) of one of the latches that was too loose.

Suffer the usual end-of-project postpartum depression.

GODDAY –

The Gods waved their beneficent parts in my direction; The Gods laughed upon me.

As the beneficent waving, my last fungible lifeline continues to surge upward which has the effect of postponing my immanent assumption of a new career in the transportation industry for a few weeks.

As to the laughter, why should not The Gods mock me?

As the Borer Crate has been delivered into the hands of its user, who expressed to me his satisfaction in a manner perfectly attuned to the special needs of a penurious artisan, I can now fully concentrate upon the Kohl Cenotaph.

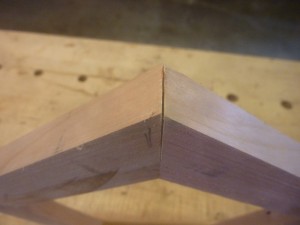

Job One: rip out a test set of five parts to ensure that the mitre gauge, which I left in its 54 degree angle from the Prototype, will indeed duplicate the joints necessary for a five sided figure which both the base and the top of the Cenotaph will/must be. This test is only the affectation of how weak is our confidence in making five-sided figures. There should not been needed sucha recapitulation.

And The Gods Laughed.

WHAT! The figure does not mesh. How ….. why …. What ….. Huh?!!!

I spin to catch The Gods chuckling, but They are too fast for me. I’m all codswalloped. The half angle of the full inside pentagonal angle (108 degrees) is 54 degrees. The mitre gauge checks out at the angle. How Can This Be?

While I cannot claim complete success in the technique of ignoring problems until they go away, since I’m so gobsmacked right now, best to put the thing down and stew over same during tonight’s Midnight Study Hall and turn to that which I can do.

Specifically, cut the insert dadoes’ in the verticals of the Cenotaph into which the sides of the 5 side panes will slip. On hopes …

Instead of installing a dado blade in the table saw, and then sneaking up on the dado width with test pieces, I left in the normal blade, made the first rip (after setting the depth of cut to about 3/16”) and then adjusted the fence to move the cut to, in the end, the desired 0.8 cm. Not using the dado blade had the additional benefit of keeping in place the zero-clearance insert which was thought needed for vertical part stability as it slid over the blade.

With the vert’s dadoe’d, I can now draw a full scale plan view which will give me the length of the base parts, which turn out to be 18 cm on the long end of the – we hope – eventual when The Gods Stop Laughing band saw mitre gauge adjustment.

Surely.

Even though behind schedule on the Cenotaph, but keenly aware of the weirdness of the mitre gauge NOT forming the anticipated joint, turn to an infrastructure project: a flying shelf for the Project Gurney.

The not-all-that-new Ed’s Sled with 1/16” incremental sliding box joint jig needs a home. It’s been camping out on the rotary tool turret on the Slack Deck, and then squatting underneath the work bench. Neither are suitable for its ungalvanized threaded rod or its meter long and 20 x 30 cm bulk. Thus the need for a suspended shelf under the top of the Project Gurney.

In conception, simple: ½” ply with support strakes ‘neath spanning the gurney about 25 cm underneath the top. It’ll be supported by four right angle brackets screwed to the four legs. Getting there was all the fun.

Thanks to surplus from the Borer Crate, had just the right length and width of ½” ply – all it needed were circular cut-outs to clear the gurney legs. This was accomplished with a forsner bit and some swearing, with a cameo by the Dremel rotary tool.

I could have welded the angle brackets to the gurney legs, but opted for drilling holes and employing sheet metal screws. To finish, four wood screws from underneath to lash the brackets to the ply.

Result: efficacious and shop-stylish. You be the judge.

ANGLEDAY –

Yesterslack: The Agony of Defeat

Todayslack: The Thrill of Victory!

Tried all night to forget about my inability to form ten 54 degree angles; nothing for it but keep trying.

Chip’s angle gauge shows that the prototype joint angle is 54 degrees and this is what the mitre gauge is set to.

The Gods did indeed forget about me today, and left to my own purposes without celestial interference was, in the fullness of time, able to form the angles for the five-sided Kohl Cenotaph base. The fuck of it is that I did nothing today I wasn’t doing yesterday.

There was some fine-tuning of the angles by hand and eventually the joints were tight enough for this job. But we will only know for certain once the thing is out of the clamps.

With this heady accomplishment, can I form the pentagonal top piece? Nothing to stop me. These joints need to be even tighter as they will form the second thing the eye will see in the finished piece.

Much, much fine tuning, but in the end, tight enough. I hope.

REWORKDAY –

Back to the Agony again: four unacceptable gaps in the 108 degree joints. This mandates Try Again.

Back to the Agony again: four unacceptable gaps in the 108 degree joints. This mandates Try Again.

Whilst summoning up my re-work chi, formed the pseudo-tenons for the base end of the verticals. Pseudo as it involves merely knocking off the sides of the two outer flanks just to the dado line.

Now, for the re-work. Had no more fine poplar, but had some handsome mahogany.

Didn’t stop to form the top differently from the base. Too late in the game for that, I want to get this project done, and I’m sick of looking at five-sided figures.

The dry fit of both base and top were close, but not close enough. What followed was gentle hand-sanding off the heel, a couple of strokes at a time, and then clamp up to test the fit.

This iterative process felt like it took longer than it did, and in the end, there was glue up. Is this set acceptable? Won’t know until the morrow.

This week the not-all that-new drawbridge has enjoyed the attentions of Paul ‘The Painter’ Drake. Former golf hustler, pool shark is today’s consummate workman and collector of valuable baseball cards. He threatens to commission me to make for him an internally divided case for about 80 of his most valued cards.

The job might be too much for his purse, and too much groove routing and partition cutting for JohnsonArts. We shall see.

We’re talking and it turns out that his older brother, a retired oncologist, built during their boyhood model planes and he zooms in on the B-17 hanging in The Shop. Had an uncle who in WWII was a B-24 gunner, saw duty, and this was unusual, in both the ETO and Pacific.

His brother and uncle go car shopping one day, this day to the Mitsubishi Dealer. Salesman is right on the spot, “Well sir, have you ever driven a Mitsubishi before?” Uncle: “No, but I shot one down once.”

HAPPENDAY –

I owed the Glasswegan the pattern for the sixth and last piece of glass – the top piece – for the Kohl Cenotaph. This template I delivered to her at her studio in Carmel. In return, I was handed an in-line dimmer switch that I’ll put in the cord to internal light.

I’m at the point in the project where I can see it coming together, can taste the money when it’s finished.

Those sticking out bits are the faux tenons that will seat in the angle and rabbet of the five corners of the base and top.

First – cut the five verticals to the desired length allowing for the sort of half-tenon that seats into the rabbit in the top. Once the verts are to length, shave off enough to form the sort-of tenons and fine tune.

Second – drill the holes in the base, mark those hole positions on the bottoms of the verts, and then pre-drill into the verts for the screws.

Since the top must be glued onto the top of the verts as well as I know how, the base must be removable for the replacement of one of the panes should ever one break. I argued against this – this is not a 100% Life Time Guaranteed Ginzu Knife set – If it breaks, too bad, we’ll make you another one. But I conceded and there’s no loss of physical integrity in NOT gluing as well as screwing on the base.

Third – drill into the top for dowels, shallow as I had only about a centimeter for thickness, then mark and drill the holes in the corresponding tops of the verts.

There’s always one SOB in the bunch: Vert 1 had a misplaced hole, twice, and it’s still wrongish, but I’ll rely on the Monkey Glue. Say NOTHING.

Fourth – final sand and put some tung oil to the parts. Since I cannot finalize the tops of the verts until I have the sixth pane, I can assemble not. I DID dry fit the thing with the five side panes and discovered that I had 1/8” of slop too much on either side. What!???

The faux piece used to test the fit was correctly sized. The full-scale drawing was correctly drawn. The parts were formed to the full scale drawing. The Gods Laugh at me again.

Fortunately, there’s just enough giche goomie of cover that with the judicious application of some hot melt glue during final assembly, I can cover the potential gaps. Phew.

RUNDAY –

But only in my dreams.

To earth, The Prof calls, asks can he stock The Shop fridge with beer left over from his soirée last night? Wadda guy.

Next, The Glasswegan arrives promptly at 10AM to deliver the sixth and final glass pane for the Kohl Cenotaph – likes the look of the pieces in pieces. If I hustle, can assemble the thing today.

But I didn’t hustle.

Just as I’m getting set, The Prof arrives – how about a trip cross town to Homely Despot? I figure he’s just trying to cheer me up, but on the other foot, if Beer Delivery doesn’t cheer a body up, what will? Don’t answer that, you know what.

But no, he needs some technical assistance horsing ¾” ply around.

I take the opportunity to ignore him and browse, look for ideas on how NOT to cut 160 grooves and 80 partitions should the Paul Drake Card Case advance from the arm-waving stage to a paying project. Two ideas occur: 1 – instead of partitions, why not insert the card cases into a U-shaped channel, and 2 – picture a shutter with fixed and relatively tightly spaced louvers laid flat, what have you? You have a sort of reclining set of slots into which to insert card cases.

Back to The Shop, kerf the tops of the verts to accommodate the sixth pane and test for fit.

Install the ugly (as mandated by The Glasswegan) feet, then assemble the light socket and wire the thing including the male plug and an in-line dimmer switch.

All the while lathering on the tung oil. Five coats thus far, needs at least two more. Since the customer will not be available until next weekend, there’s no need to hustle, except to payday.

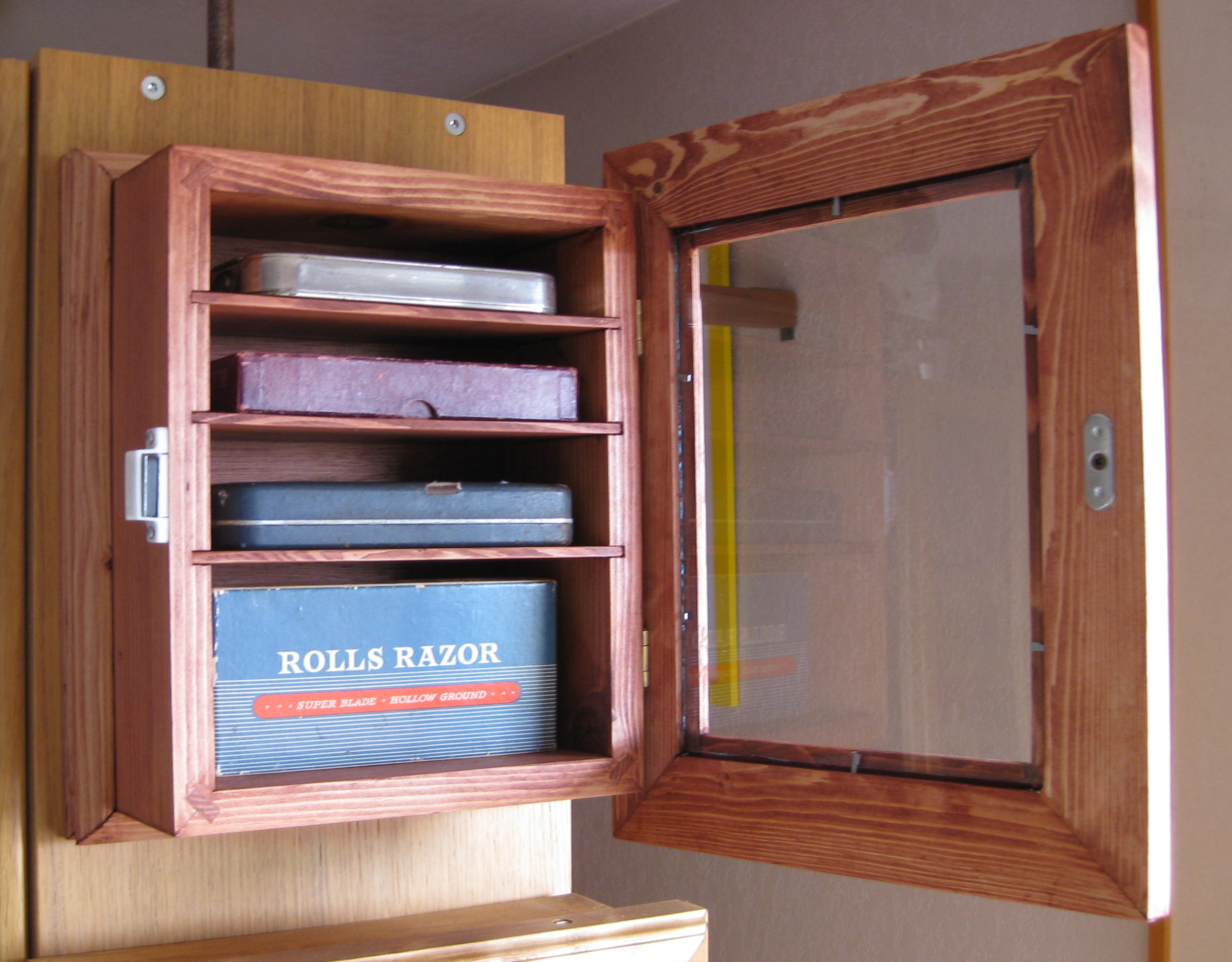

Twyla’s Quilting Scraps Cabinet

Twyla’s Quilting Scraps Cabinet  Vadim’s Curio Case

Vadim’s Curio Case  Sewing Needle Wallet Display Case

Sewing Needle Wallet Display Case

No comments yet.