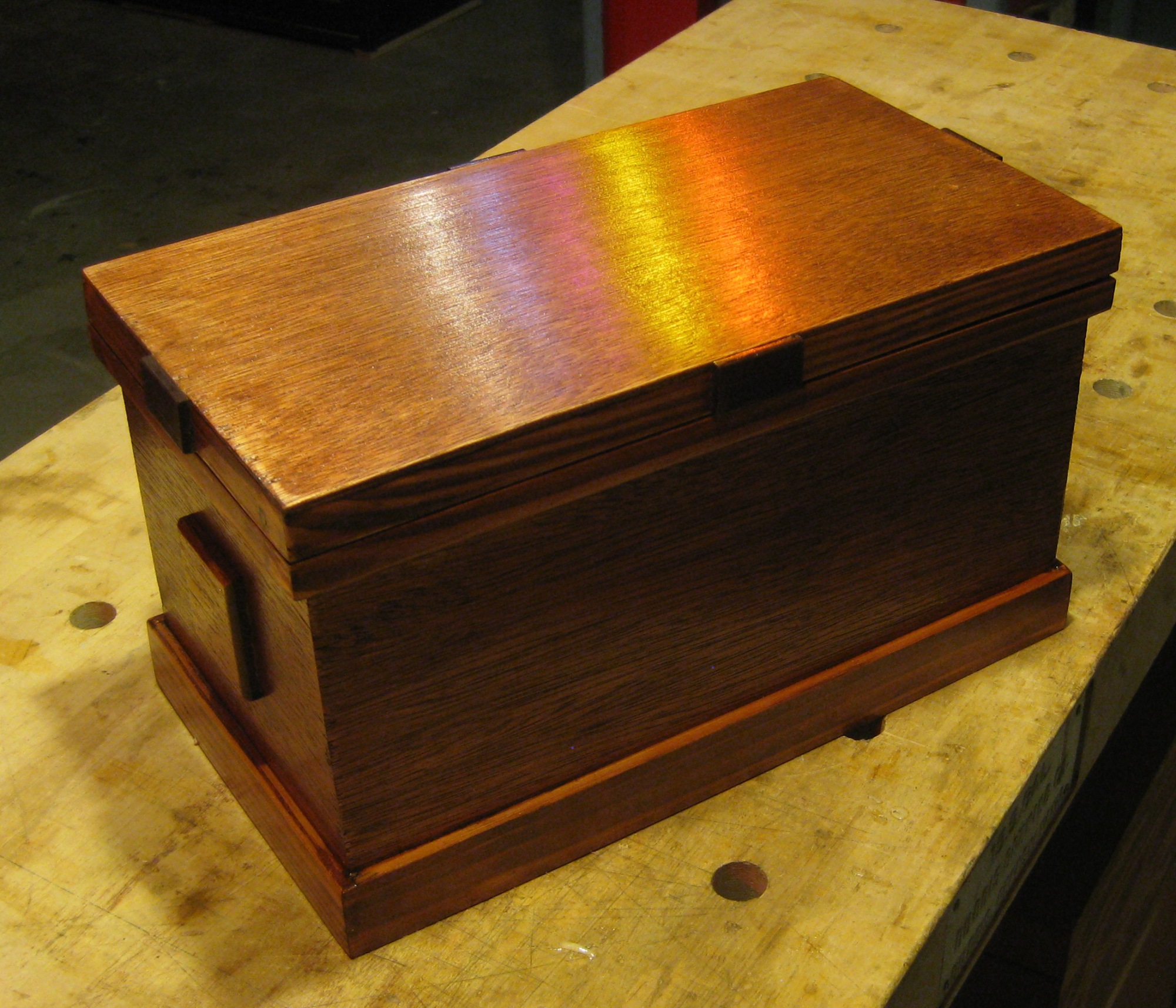

Box Joint

Good drifting, except for the lost truck, again and not being able to wake up when I realized I was in a dream.

Good drifting, except for the lost truck, again and not being able to wake up when I realized I was in a dream.

Dentist visit – all is well, his wife, if I didn’t know (think or not want to think) better, wants me to do her. And I would, for a thou, send Viagra.

Minding my own blog posting business when The Prof arrives with a half case of Sierra Celebration and job guidance. I welcome the one.

He was more snarky than usual to which I attribute the sense of the long, winding story about some colleague and in the end, a guy who up and died two days ago. The Prof’s age. Sensing his mortality put him on edge. It does anybody.

MUCOUSDAY –

I have apparently been behaving as not sick such that the evil invading organisms took this as an opportunity to double their debilitating efforts. I feel it. And so resolve a quite, peaceful, restful, tranquil, sedate day.

Right after I get to TJ’s for the early week O’boom rations, spin to Homeless Depot for a pair of cabinet locks for the Colton Hall donation pedestal, out to The Dump where crap stockpiles are at an ebb, but Hosanna! The Toxic Table serves up nearly a gallon of denatured  alcohol (shellac solvent) and half a gallon of acetone (wood putty and Gorilla Glue solvent). My chemical shortfall is at an end! So too the end of having not chicken for the pot as Grocery Cheaplet offers $1.59/lb whole dead bird for the stockpot. Even though I am not eating lunch these days, I foresee, I hope to see, stormy winter days, the Castle lashed with the tempests of the Pacific during which a hot steamy bowl of soup would add savor to the scene. Chicken got, need a sack of frozen veggie, not got. I’ll wing it.

alcohol (shellac solvent) and half a gallon of acetone (wood putty and Gorilla Glue solvent). My chemical shortfall is at an end! So too the end of having not chicken for the pot as Grocery Cheaplet offers $1.59/lb whole dead bird for the stockpot. Even though I am not eating lunch these days, I foresee, I hope to see, stormy winter days, the Castle lashed with the tempests of the Pacific during which a hot steamy bowl of soup would add savor to the scene. Chicken got, need a sack of frozen veggie, not got. I’ll wing it.

Wing it back to the Castle where the dead bird is immersed and scalded. Veg? Have a 4 pound bag of Asian stir-fry, it’ll have to do. Soup, it isn’t a recipe, it’s what you have and what you have goes into the pot. And it did.

Along with onion power, celery salt and historically significant basil flakes from the bottom of the spice locker. In sum – it is the most piquant, savory, satisfying soup I’ve ever made. Strange.

HEY! Here’s the check from SPAR for that 11 hour training day two weeks ago. The sum is twice what I’d expected. SPAR is shifty about what it pays; there is no on-line itemized list of what the services of the Independent Merchandiser can expect for his labors. Semi-negotiable? Maybe.

I’ve opted out of the in-store jobs, not that I minded going to the three Staples, except for the trek – Morgan Hill, Gilroy, and Hollister – it’s the dusting the display furniture at which I balked. I don’t dust, not even for fifty cents an hour.

LONGDAY –

Six hours straight at the Donation Pedestal. If I had known the extent of the work two weeks ago when I swagged up the bid, I would have doubled the hour estimate; which would have frightened both the potential client and me. Probably a Real Guy could/should have done what I did in half the time. I’ve always been slow.

But off to a fast start at 11. Trying to put off gluing up the four verts, cast about for anything I could or should do that would be more difficult once the box is a box.

Washed all the parts in Murphy’s Oil soap then let them dry while I was installing the locking latch on the door, the same type locking latch that will secure the drawer, but drawer installation awaits box assembly.

I only dicked up the latch installation in the worst way possible – by drilling for the lockset overfar from the case so that the swinging dingus missed by exactly the gap of the door. All I had to do was install the lockset TOO Close, discover that it was too close, and then grind it down. No. Instead, I had to move the lockset hole about half a centimeter toward the edge of the door. Happily in this unhappiness, the trim flange was wide enough to cover my prang. Yeesh.

Pedestal glue-up showing the fenestration for the door below, and for the drawer, the rails for which can be seen uppermost.

Nothing for it but to glue up the four verts and transform firewood into a pedestal. The meet edges are rough, raw and gappy, in so far as I could tell before the Gorilla Glue started exuding. So be it.

Now that the box is a box, can cut the floor from ply and nail it in. Naturally, I choose some old ply that happened to be 1/8” thicker than the cutout I had factored into the base. A discovery made only After I’d put glue to the box and put the ply in. No, it’s GOOD. A bit of an offset between the box the four feet will add visual appeal. Really.

Now for the box top. This ‘top’ is really the ‘floor’ for the acrylic box where the lovely spondulicks will repose once slipped through the box slot, and a show surface. It also wants a 4” square hole in the center.

A Real Guy would likely have plunge routed the hole.

This guy drilled four holes at the corners, sawed the dross free, and then deployed his Dremel tool and sandpaper to finesse the fenestration.

Clarity of mind – in short supply this day – materialized for a fleeting moment otherwise I might have glued the ‘top’ to the box top, which would have been madness as I have yet to fit the drawer, a fitting that will be made straightforward (not simple, but straightforward) with access to the box from the top.

Now, the final, major assembly task: form the trim that will hide the ply/vert seem on the top and secure the acrylic box.

Swathed in tape is the clear, acrylic box which will surmount the pedestal, I’m test fitting the box into a groove I’ve crafted in the top trim.

Had the bottom of the original door available from which I rived four 5 cm thick slabs that once 45’ed, will form sort of a picture frame. Kerfed to match the footprint of the acrylic box, said box will nestle into said kerf and drill through and screw will secure the clear box to the pedestal.

Thus: roughed the 45’s on the table saw using the sliding mitre attachment, then deployed Godzilla the Miter Trimmer. And Godzilla Must Die. I’ll set the angle to the 45 preset – it’s a pop up zoit against which

registers the movable fence – trim an angle, then forget to notice

Godzilla the Shifty – the cutter works wonderfully, it’s those adjustable wings that set the mitre that I cannot convince to remain where I set them…

that the fence just moved, and it moved again. This even with plier tightening the set screw. I must be doing something wrong, but here is a tool that has a pre-set stop, an adjustable pre-set stop at which the fence does not stop. If I had any hair long enough to grab I would have pulled it out.

Just then, I actually pick up the phone

when it ‘rings’ and I was glad that I did – it was Theresa, the glass artist. Her latest venture – well, it’s actually an excursion on the dog veneration box we talked about weeks ago – is a pentagonal, glass sided sepulcher inside of which is an old style mechanical music box. Fine, but she wants the top of the box to rotate as the music plays. What I truly appreciate about these cockamamie schemes is that it saves me from having to think up my own.

She’s got a graphic designer on the phone who is going to render the piece in 3 D so that the potential client can grok the vision. All well and good, but will the mechanical music box actually fit inside their dreams and more importantly for the kineticist who will have to build the thing, has the wind up mechanism sufficient torque to drive anything other than the cylinder of tines tripping the forks to play the tune? And even if there is sufficient torque, how does the artisan working in physical 3 D link the spring drive to turn the top of the box? All good fun.

All the while those four trim pieces – show features second only to the clear box itself and the cash floor – are getting shorter and shorter as I desperately try to keep Godzilla in harness. Would have employed my usual practice to fine tune the 45’s, which is to rely on the 10” disc sander which is set for 45’s, but the width of the trim extends beyond my setup.

Somehow, I harness the evil forces of Godzilla for my own purpose.

Now, dry fit the trim and put the acrylic box on the trim so as to guestimate where to rive the 2 cm deep kerf. I get this about right.

I’m tired, if this had been one of my own ventures, I would have quit two hours ago. But no, that invoice is in work, the check will be mailed Friday and I’ve promised to deliver the pedestal by Sunday.

Just a few more tasks: drill and countersink sideways to the trim through the kerf for the four brass screws that will fit through holes in the acrylic box and thus secure said box to the pedestal. Then find my 3” long tiny headed screws which I predrill for through the bottom of the kerf – this will hold the trim to the top of the pedestal, and be unseen.

NOW – can glue up the top trim.

Much remains to be done: fit the drawer and drawer front, install the drawer lock, put in the door, affix the top trim and then the big job: try to make the fresh surfaces look more like the 80 year old patina. And try to ameliorate the gaps at the edges where the verts join. Send Real Guy.

SURPRIZEDAY –

And not in just waking up after skating graves and Georgia and Harvey moved into the basement of the Singing Hills place either.

Yesterslack devoted 6 hours to The Colton Hall Donation Pedestal, not without merit, but it seemed as if I wasn’t advancing, and this puts me 4 hours over my time estimate and 12.5 hours. And to today felt demoralized – it is possible to feel something other than pure elation at working a project for which payment is immanent. Fretting about the yids and yads, cracks and crevices. Dumb. I know.

Feelings aside:

Drilled/countersunk the screw holes for the pedestal feet, then applied same with glue to the underside of the crate, ahem, Donation Pedestal.

Now the door – installed a strike plate on the inside of the box where the latch will latch, even though I need not.

Door fits well, better than the test fit last week. Today’s first pleasant surprise.

Now, trim.

Never cut trim, particularly ¾” quarter round, always buy it, it takes longer to make it than it’s worth. Did that stop me?

It didn’t. Had leftover fir from another venerable door which I used for the trim, it actually took less time to make the four 72 cm lengths than it would have to drive to Homeless Depot, although I hadn’t factored in the $0.02 cents for the electricity to run the table saw.

And that was the EASY part. Discovered that through disuse, I no longer know how to tap in a small finishing nail so that it doesn’t verge out the show surface. Much remediation, curses and black moods.

To the Drawer: fuck up 67 ways to 83 all the possible ways to fuck up by kerfing the front, then the back and then doing it AGAIN before settling in on actually kerfing the two sides for the slides. But if we ignore that, we can be thankful that I snuk up on it and the drawer fits on the slides, and even slides. In AND out.

Pre-fit drawer face using beer coasters to evenly position the drawer face inside the cabinet opening. Having previously pounded nails (heads cut off and sharpened) into the false face of the drawer – the face that will snuggle up to the back of the real drawer face – I could smooge the drawer toward and into the reverse of the real drawer face thus marking where said face ought to reside.

Now, can install the drawer lockset, which was done, not without much sturm und drang fitting lockset, including countersinking at the back of the drawer face to allow securement – have to scarve out ply to allow lockset latch to travel.

Feel like I’m bogged down, making progress but not getting out of the project swamp. And then, it Happened.

Two things. Existentially, I suddenly realized that I was creating a New Antique.

Old wood, new purpose, new furniture, but sensitive to time. It was a game changer, I wasn’t building a donation pedestal, I was recreating something that should have already existed.

Physically, the second game changer was when I slathered on the Red Mahogany stain on the fresh surfaces of the fir. It was close, it was Very Close to the original tone, and then it got better. When wiping the RM stain over the old wood, it not only freshened, cleaned and brightened the 200 year old fir tree product, but brought all the parts, new and old toward a common tone. This unified the piece in a way I could not have anticipated.

This Piece Might Be Good.

Happy, drained, tired, and so stand down. Just then arrives The Prof with medicinal Irish Tonic and he IS the Doctor.

DELIVERYDAY –

Shop open early, not the 4 AM when I was awake thinking about opening The Shop, but almost, sort of….

We can finish the Donation Pedestal this today. We can deliver it today.

Remaining tasks:

Fit and secure the top, which is the floor of the acrylic box to the top of the pedestal; affix the top trim that will secure the acrylic box; drill holes in the acrylic box for the lash screws; and put a pull on the drawer.

Yes. Affixing the top/floor was straight up, nail ‘er to.

But before affixing the top trim, kerfed to accept the acrylic box, first was necessary to drill out the plastic box for the four holes through which would pass the brass screws securing same to trim.

Even though using brad point bits, in my over exuberance – drilling plastic mandates slow speeds because the plastic melts, or worse, clogging the bit – did the One Thing I Did Not Want To Do: cracked the box. The crack running vertically an inch over where it’s inset into the trim SAY NOTHING.

The clear, acrylic box is secured to the top trim of the pedestal by four screws from the inside – here is Thing installing those screws through the hole in the floor of the box via the drawer opening.

Drill the other holes with greater forbearance.

Now, put the box to the box.

Here’s the Addam’s Family Thing moment reaching up through the cash hole in the floor to screw in the screws.

Finally, do I have a sort of antique pull for the drawer in my vast collection of possibilities?

I do.

Done.

Load the thing into the truck and lade it to Colton Hall. Jeff is on station and likes the creation.

The Colton Hall Donation Pedestal installed and on duty, ready to collect the alms of the grateful historical pilgrim.

He’s not the paying customer, but it’s a good recommendation.

The usual post-partum project depression follows, so I clean up The Shop, stow the historically significant fir remnants and then, another commission arrives.

The Prof bearing an almost impossibly repellant print and four wine grape stakes out of which he expects a frame. An ugly frame. And he will get it.

UGLYDAY –

Even the airport dreams were unsavory, an appropriate lead in to today’s effort, once the shocking, shocking O’boom shortfall was made good and the check from SPAR deposited.

Let the Ugliness Commence.

It started with spray gluing the back of the repellant print, then applying same to some crimson matte board, which was cut to an inch boarder.

This gave the rough dimensions for the pine frame (salvaged futon bed slats), which would be, in the main hidden behind the wine stakes, but in need of the worst color paint I could lay hands on.

Anon, I rough out the pine to about 4 cm wide, then kerf for the matte board. Finish cut the hidden pine frame to dimensions – 57 x 27 cm – and make it easy on meself as the joints are butt. The pine pre-drilled for the butt joints and the attachment, eventually, when ugliness surmounts, the wine stakes. The filthy, mud encrusted, gray green riven, shattered, holed, windy, bent wine stakes.

Coat the hidden (mostly, it will be seen from the sides) frame in “Maid Marion,” which makes you wonder, somewhere, there’s a person whose job it is to develop names for common articles, like faded lilac paint, which will sufficient clash with the tones both of the repellant print and the crimson matte board.

So Far, So Bad.

Whilst the noxious colored paint it drying, case the dreck brought me by the client. Amid the used Sawzall blades, tacks and tackle, there this a gem: a cast iron mermaid, already with hanging hardware. Clearly, the frame should hang by this, via fluorescent nylon cord, strung from the nipples.

Drilling out the nips wasn’t straightforward as the teets were difficult to get a nail set into into which the drill bit would not skate off, but with perseverance, and no little Three-In-One Oil as drill lube, the holes were made.

Now, the lilac paint is dry enough to assemble the frame with the print on matte board inside.

Finally, time for the Real Ugliness – lam on the wine stakes. Choosing the most irregular, warped, and filthy, I put the two long sides on (screwed to the hidden frame from the reverse, then fit in the two short sides, again, as butt joints.

And it looks like acne asshole butt funk. You get lucky sometimes.

And yet, there is more. Some rusty bent nails, staple loosely a pair of lures, and the climax – tack on some sheet metal. Epoxy onto the face of the mermaid a hollowed out human skull just the appropriate scale. It’s hideous.

Done. It’s the most repulsive thing I’ve ever made. But in knowing that you cannot make a thing ugly enough, there’s a sort of freedom you don’t enjoy when you’re 20 hours deep into $5/board foot cherry when any mistake erases time put in and ruins the wood.

I urgently email The Client to please, please collect the abomination as soon as possible, and get my wish, just as Mozart’s Piano Concerto in D minor is in its second movement, up drives The Client.

I warn him that in spite of being a Man Of The World, he ought steel himself against what he is about to see. Well that I did. Originally conceived as a gift to a hated (beloved) friend, The Prof now thinks he’ll keep it. I could have no finer compliment, except for the cash he hands me.

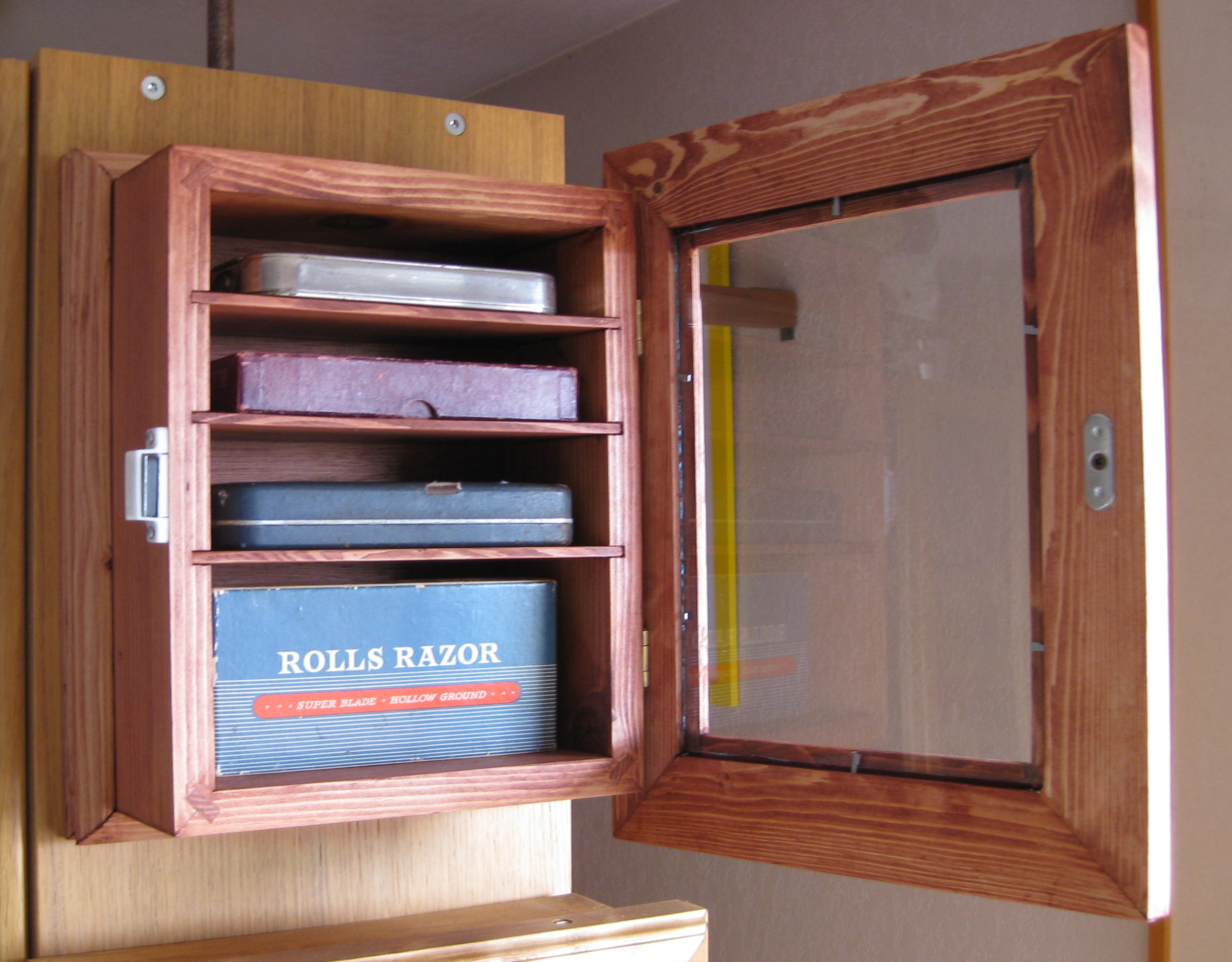

Display Cases

Display Cases  Display Tables

Display Tables  The Hoopladrome

The Hoopladrome

No comments yet.