Product Description

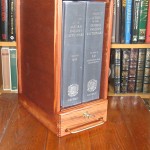

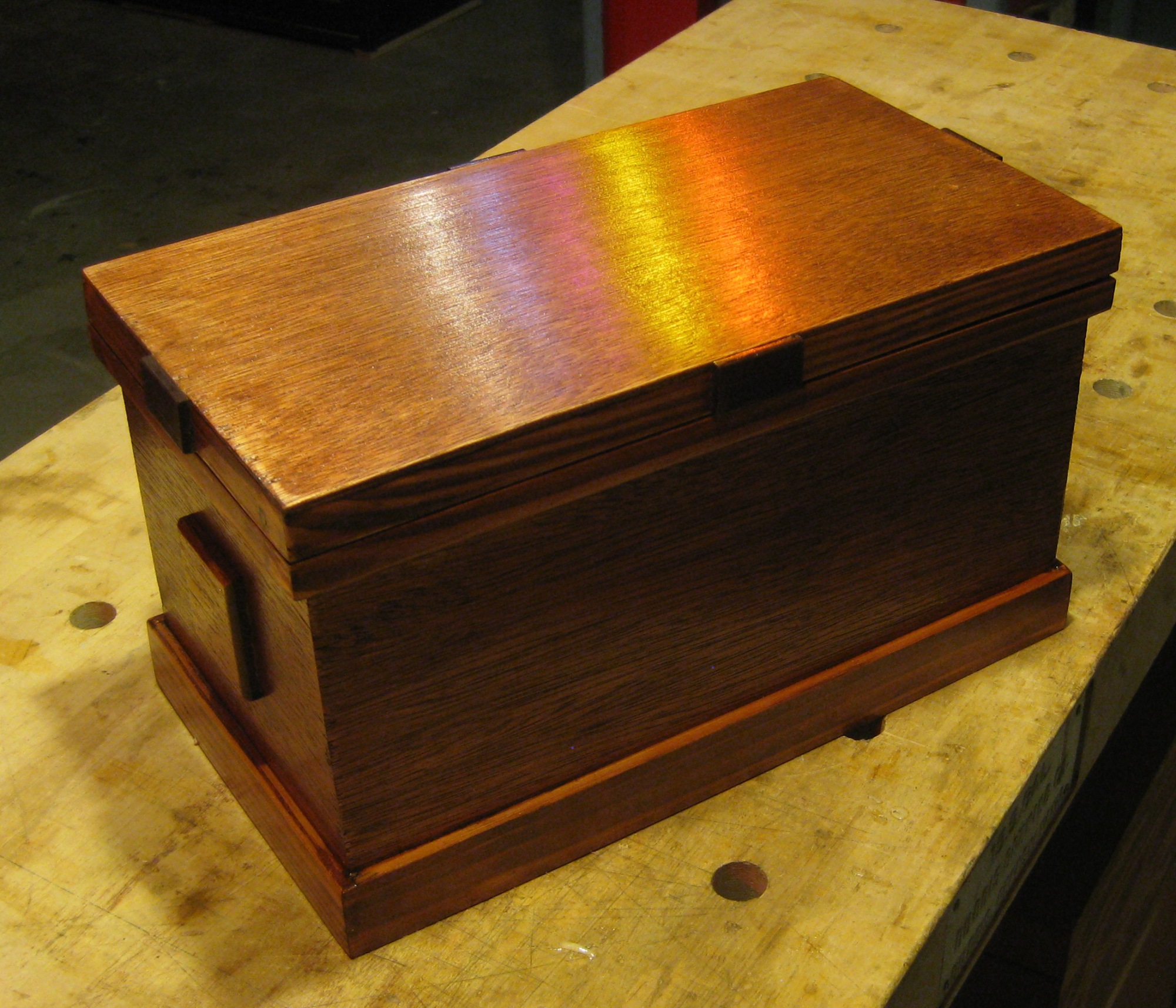

The Captain wanted a table for her printer. The antique Craftsman desk I had repaired was too high for the Fiat sized printer. And so the spec’s were 20” square on top, and 24” tall.

In oak to emulate the desk.

My design was simple and straightforward: standard apron (with a bit of a curve) and two shelves below.

In red oak, stained red mahogany.

The hardwood mill had 10” wide oak planks, but in squaring the edges I could not quite make the required 20” width. Let us make a virtue of necessity by running a strip of redwood between the two oak planks to come up to the 20 width.

Added a nice element, I thought, and so did the Captain.

The lower shelves too.

The only other excursion from typical table construction was that I used pocket hole joinery both to lash the table top and the legs to the apron.

Risky.

A more traditional method is to use S or Z shaped brackets, screwed to the underside of the table top, but riding unfastened in a routed groove, inside face of the apron. This allows the table top to expand and contract in response to more or less humidity.

Yet, the antique table had the 1915 equivalent of the pocket hole joinery, and that desk top was twice the width of the printer table.

So I went for broke on the pocket holes. Used pocket hole joinery for the shelves as well figuring good enough physically since this is oak and the shelves were unlikely to be heavy loaded, there being only 5” between them.

Using pocket holes to join the legs to the apron was another calculated risk. Had this been a larger table, and no shelves, using pocket hole joinery – apron to legs – would have been madness. The rigidity of the shelves as lower bracing unified the structure such that pocket holes from apron to legs would not be physically weak.

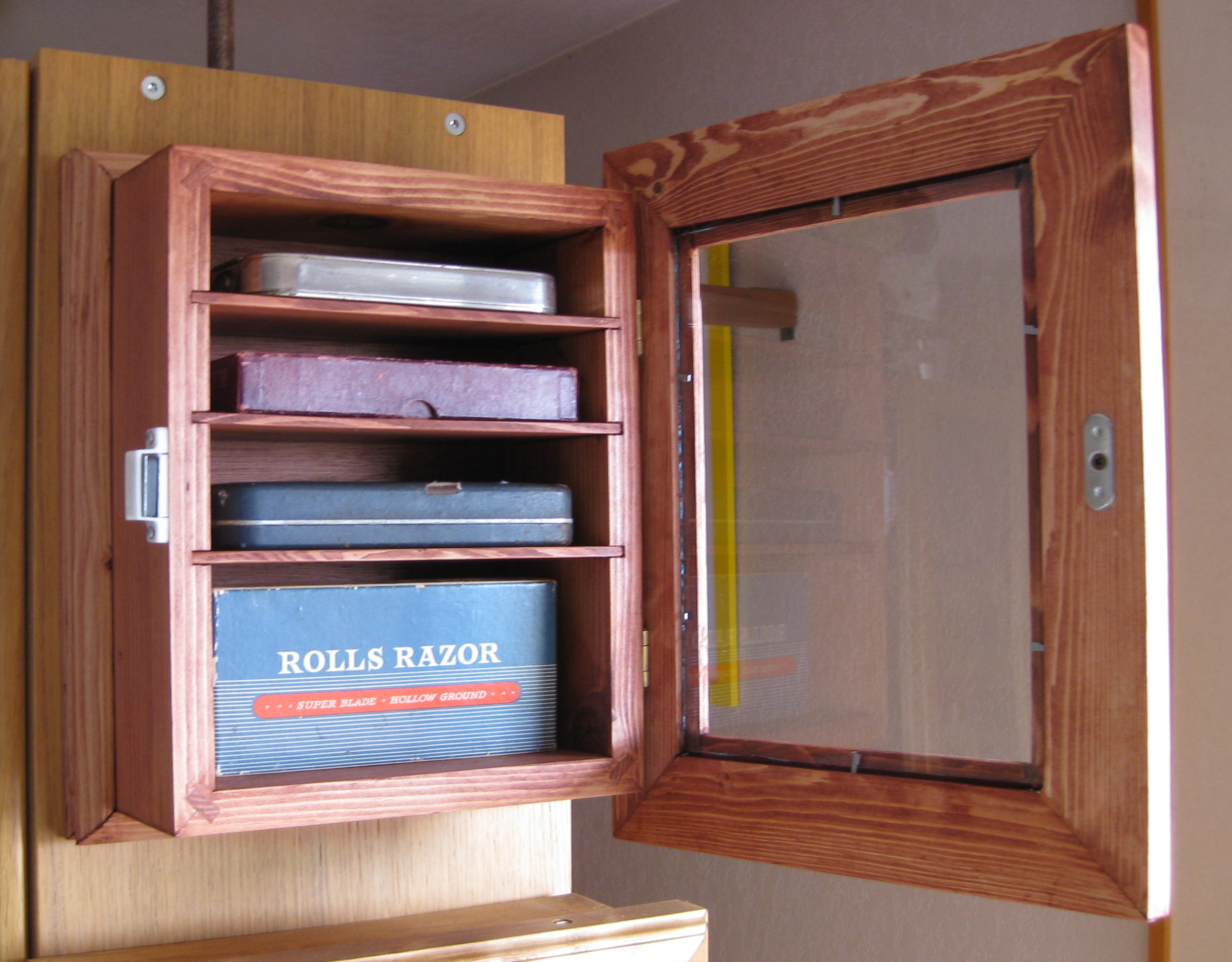

Dartboard Cabinet

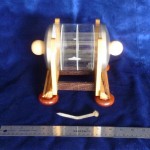

Dartboard Cabinet  Contrast Flat File

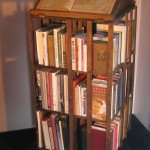

Contrast Flat File  The Gargoyle Chandelier

The Gargoyle Chandelier

Reviews

There are no reviews yet, would you like to submit yours?